Blog / 2017.11.08

VIDEO – Why Total Indicated Runout Is Important When Selecting Your Polyurethane Rollers

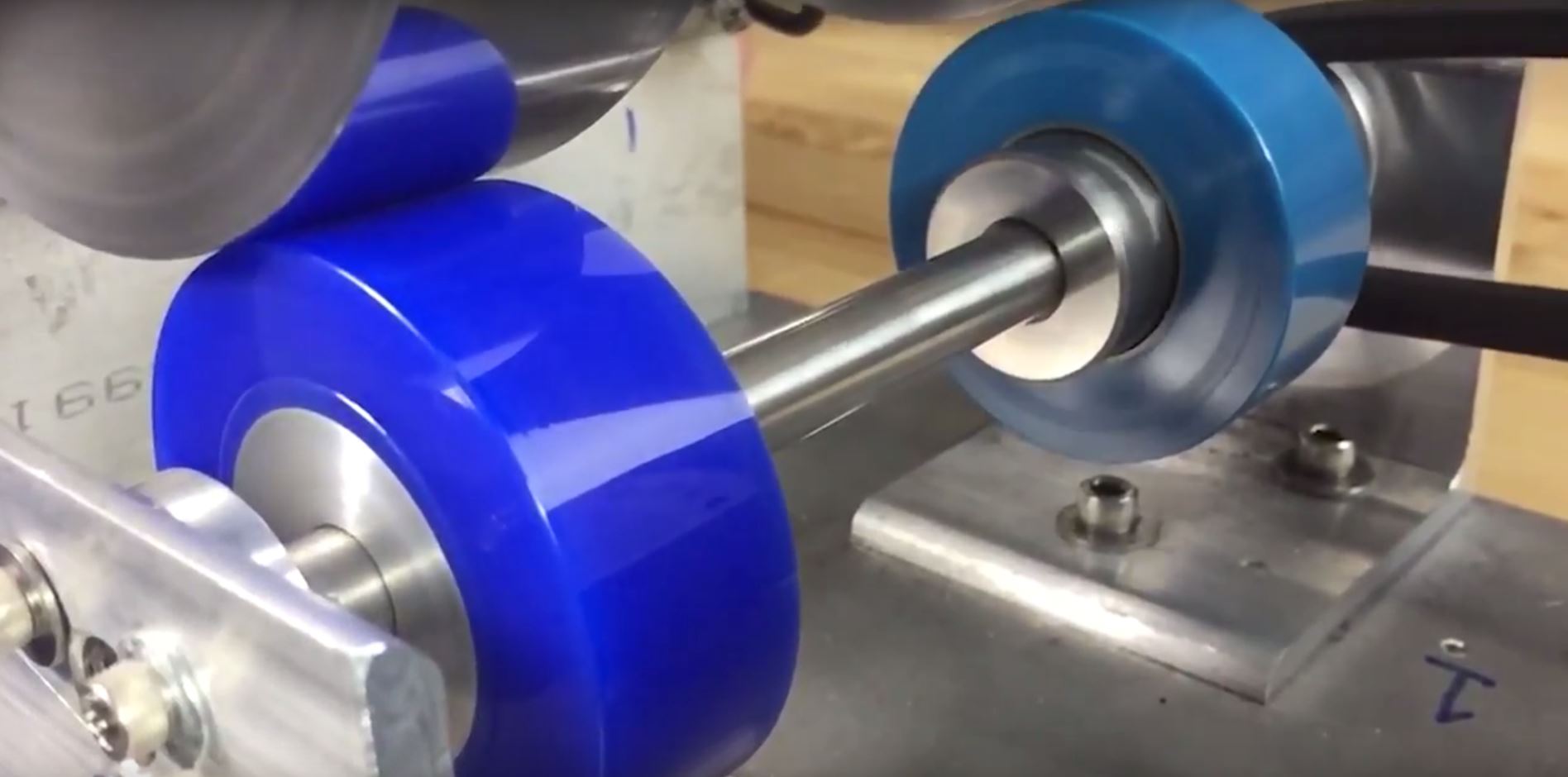

Here at Meridian Laboratory, we pride ourselves on our ability to create products of excellent quality and for our ML6 rollers, this obsession with quality extends to what is called total indicated runout or TIR. Total indicated runout is an important variable in roller design, as it indicates how concentric an object is, or how much deviation there is between the two sides at any given time. This deviation can cause problems with quality and the length of life of our rollers. In the video below we show exactly how Meridian Laboratory ML6 products are superior to the other products available on the market, with a focus on TIR.

For more than 50 years Meridian Laboratory has created quality products using ML6 polyurethane. As a true innovator, ML6 was developed in-house by Meridian Laboratory, and is scientifically formulated for exceptionally high-friction and low-wearability characteristics. No matter what your order size, industry, or application, we can create an ML6 solution for you. For more information about our precision Polyurethane ML6 you can either visit the ML6 product page, or Contact Us directly.

More Information:

Total Indicated Runout (ML6 Drive Rollers)

Oftentimes throughout our website and literature you will see us mention total indicated runout, or TIR for short. TIR is the measurement of how concentric an object or surface perpendicular to the axis of rotation of a part. A higher TIR indicates that the surface which is being measured is less concentric to the flat or surfaces being measured than a lower TIR. Ideally, a roller or anything which rotates would have a TIR of 0.000”, meaning that there is zero deviation between one side to another side of the object being measured. TIR is commonly measured using a dial indicator, which are sold with varying degrees of accuracy depending on the application being measured.

In this video we are comparing a standard, off-the-shelf competitor’s roller against a standard, off-the-shelf drive roller produced by Meridian Laboratory. Nothing special or unique has been done to either roller to achieve the results shown. What we see is that the TIR of the competitor roller to be 0.008”, while Meridian Laboratory’s ML6 drive roller measuring only 0.0005” (yes, that’s 5 tenths of one thousandths of an inch); this means the competitor roller had 16 times the amount of runout to that of Meridian Laboratory’s ML6 drive roller.

Some may question what effect can 0.0075” of difference in runout really make? The answer is surprising and is best witnessed by the amount which the competitor roller bounces off the mating surface of the test fixtures, due to this high total indicated runout. While seemingly insignificant, this bounce can lead to problems such misalignment of products being fed by the roller, a misreading of an encoder signal, vibration, or misses and jams in a feeder application, among other problems.

Meridian Laboratory’s unique and time-tested manufacturing methods guarantee a low total indicated runout, regardless of durometer or quantity ordered. By using Meridian Laboratory polyurethane rollers and products you can be guaranteed to get a superior part which has a near zero total indicated runout. Meridian Laboratory rollers are extremely concentric and have a TIR typically under 0.001”.