ML6 polyurethane belts are a great alternative to the traditional poly cord. We manufacture belts to exact circumferences in any width for your specific application. ML6 belts offer the same great friction and low wear benefits, but without the drawback of having a weld seam. Meridian Laboratory belts are seamless and can be used at much higher tension than typical belts. This combined with the high friction characteristic of ML6 polyurethane provides for greater friction and less slippage in the mechanism.

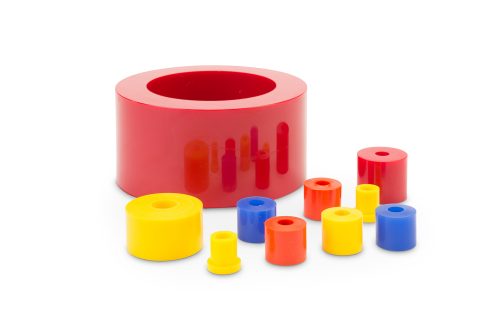

Many customers also use precision polyurethane ML6 for applications which are not traditionally a tube or a belt, but simply as a non-marking and durable material that is highly customizable, providing low volume, cost-effective solutions. Customers often use polyurethane ML6 as a gasket, seal, or bumper material including flat, round, and other shapes and profiles.

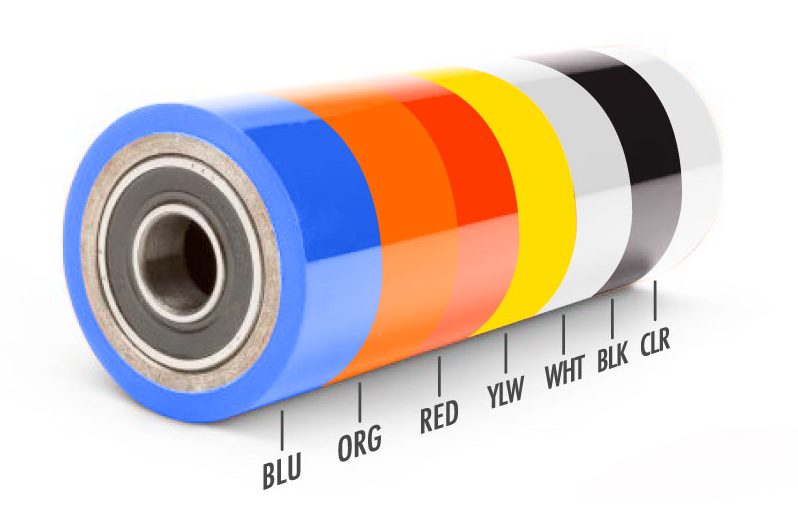

Custom colors available on request

| ML6-40A | ML6-55A | ML6-70A | ML6-80A | ML6-90A | ML6-60D | |

|---|---|---|---|---|---|---|

| Hardness (+/- 5) | 40A | 55A | 70A | 80A | 90A | 60D |

| Ultimate Elongation (%) | 640 | 540 | 540 | 640 | 500 | 300 |

| Ultimate Tensile (PSI) | 3200 | 5300 | 5600 | 6900 | 6200 | 6400 |

| Tear Strength, pli Die "C" | 150 | 244 | 332 | 421 | 568 | 620 |

| Split | 19 | 51 | 92 | 175 | 134 | 125 |

| Compression Modulus (Young's Modulus) | 380 | 830 | 1660 | 1990 | 6460 | 16200 |

| Compression Set (% 22 Hrs. @ 158ºF) | 0 | 1 | 7 | 16 | 18 | 30 |

| Bashore Rebound (%) | 50 | 41 | 37 | 31 | 35 | 52 |

| Abrasion Loss, mm | 200 | 224 | 159 | 94 | 101 | 115 |

For more information, contact Meridian Laboratory