Blog / 2023.08.11

3 Things to Consider When Choosing a Rotary Ground

Key Considerations for Selecting a Rotary Ground

Whether you are occasionally doing small jobs and repairs in your spare time or operating high volume 24/7 automated welding cells, there are 3 major considerations to be aware of when selecting a rotary ground to ensure you are producing a quality end product and increasing your revenue.

1. Performance

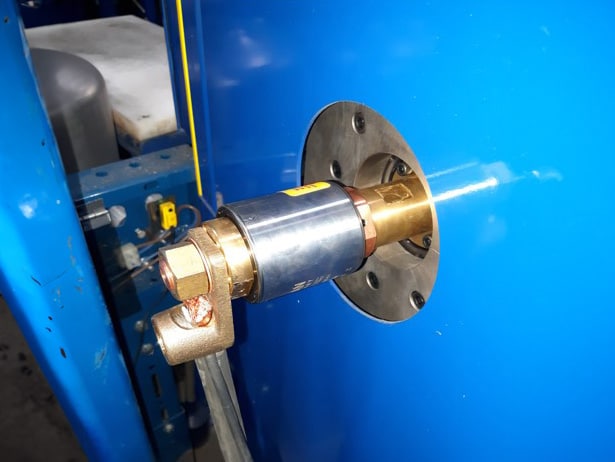

The quality and repeatability in the manufacturing of your final product is directly related to the quality and consistency of your rotary ground. If you are looking to make small welding repairs, long term performance may be a less important factor than in automated applications which rely on the rotary ground to continuously pass high current during continuous operation and rotation. It is crucial to take this into consideration, as variance caused by an inconsistent current conducted via a metal-on-metal contact equates to fluctuations in amperage, leading to under penetrated welds or blow throughs, poor or uneven plating thickness, or other inconsistencies in the final product. Poor welds, scrapped parts or wasted material means higher net costs and lower profits. As seen in this video, there are many ways to ground a rotating workpiece, and performance varies between the different styles of rotary grounds available in the market. Meridian Laboratory’s ROTOCON ERG-Series rotary grounds have been tested to over 500 million revolutions and are the only ones capable of delivering consistent current with no measurable variance.

2. Maintenance Requirements

“Industry Standard” metal-on-metal rotary grounds (offered by manufacturers such as Tweco, Lenco, Sumner, etc) require routine maintenance and adjustment to keep them operating. Anytime production is required to stop and fill a rotary ground with conductive grease, clean or replace brushes, adjust tension bolts or replace faulty rotary grounds means money lost. You are delaying the production and fabrication of your parts, investing additional money into the replacement of parts and labor, and potentially scrapping irregular or inconsistent parts that don’t meet your final specifications. If this is happening once a year, this may be a tolerable cost of doing business, if you are seeing this happen with regularity it may be time to consider the lost costs involved with your current rotary ground solution.

3. Lifecycle

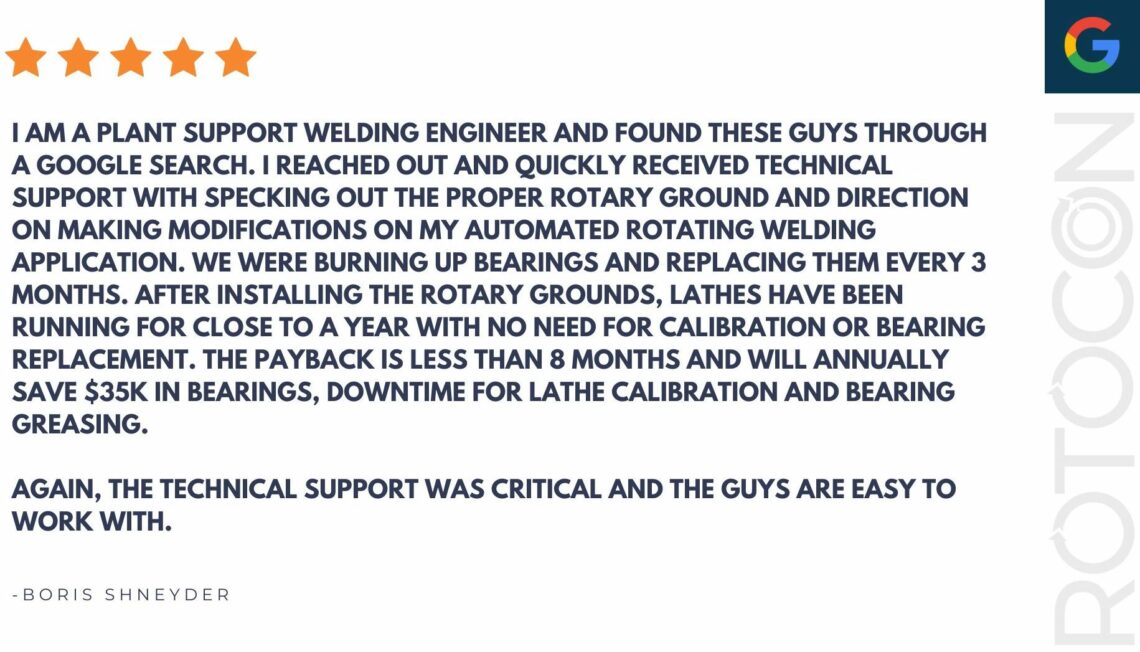

How long something lasts is something we regularly consider in our daily lives, and something that should be considered as you are sourcing a high current rotating electrical ground. If you are buying a “cheap” rotary ground, but replacing it multiple times a year, the cost of the rotary ground and maintenance can really add up quickly, and this is ignoring the fact of any scrapped or poorly produced products that need to be reworked or scrapped. ROTOCON ERG-Series rotary grounds have been tested to and surpass 500 million revolutions delivering the same consistent current throughout their life cycles. In some cases, Meridian Laboratory has seen its ROTOCON rotary grounds in operation for decades of uninterrupted performance, and our customers reinforce the quality and long term profitability of upgrading to a ROTOCON rotary ground as seen below:

Summary

In summary, the return on your investment and the quality of your process should be the driving factors in deciding which rotary ground is right for you. Obviously, cost is a major factor in sourcing a rotary ground for a project or application, but it is important to keep in mind not only the upfront cost, but also potential money saved on maintenance, downtime and replacement throughout the lifecycle of a rotary ground in your application. If you are seeing high volumes of scrapped product, regular downtime due to maintenance, or tired of replacing your rotary grounds routinely, Meridian Laboratory’s ERG-Series rotary grounds are the only solution. ROTOCON ERG rotary grounds deliver years of consistent, dependable performance regardless of total revolutions, vibration or orientation. We have rotary grounds ranging from 400A – 10kA, with RoHS compliant models available upon request. If you’d like to learn more about our rotary grounds and how we can improve your process and product, please reach out, we are happy to help.