CASE STUDY

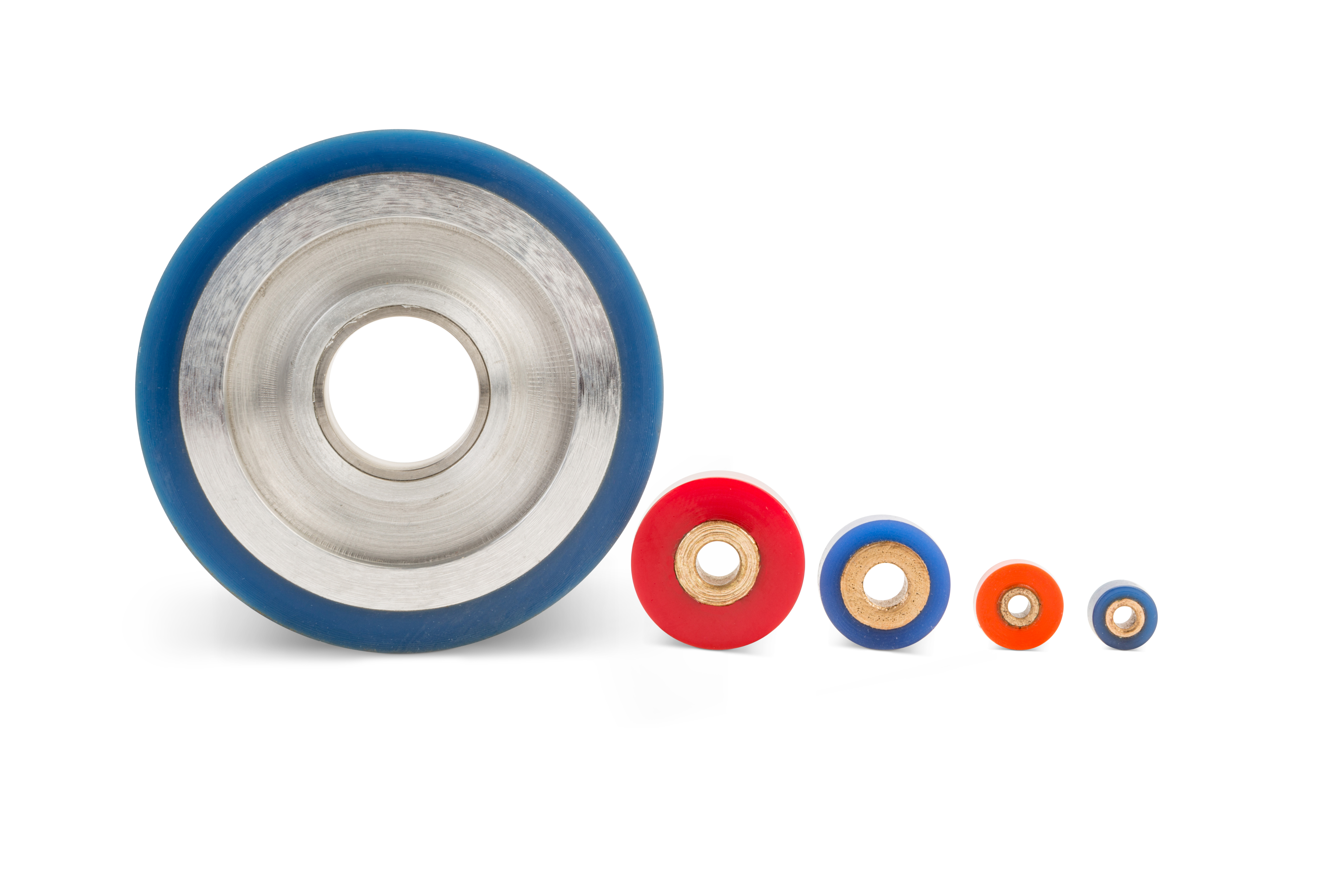

Polyurethane Idler Rollers in Less Than 7 Days

Challenge

After conducting some basic testing with standard products, available through the distributor, a worldwide aerospace design and engineering firm realized they required options and alternatives which the distributor was not willing to stock and carry, and was then directed to Meridian Laboratory.

Solution

Working directly with engineers at a major aerospace design and engineering firm, Meridian Laboratory was able to deliver low volume prototypes of their custom designed polyurethane idler rollers in a matter of days for testing and evaluation. Following an extensive test period, and tests to conform with aerospace standards, Meridian Laboratory worked to answer customer questions to further the customer’s confidence in selecting Meridian Laboratory. The customer was able to quickly conduct quality and longevity testing, qualify and evaluate the product, and advise the custom polyurethane idler rollers to be certified for mass production.

Following certification and vendor approval, Meridian Laboratory worked with a variety of end-integrators and production facilities to ensure on-time deliveries for their high-volume production orders with proper documentation, and certification of conformance.

Key Statistics

- Meridian Laboratory was able to deliver custom parts for testing and evaluation to end customer in less than 7 days, at no additional cost over stocked items.

- Meridian Laboratory’s polyurethane ML6 delivered the precise, long-lasting, non-marking, and repeatable solution the customer required to make their first class cabin trays a successful.