CASE STUDY

Signal Quality Demonstration: Conventional Slip Ring vs. ROTOCON

Slip Ring Signal Quality Demonstration

Since 1963 Meridian Laboratory has manufactured brushless industrial slip ring assemblies and rotary electrical connectors. Conventional brushed slip rings rely on stationary graphite or metal contact (brush) which rubs on the outside diameter of a rotation metal ring. Unlike conventional slip rings, every ROTOCON features a brushless oil-sealed viscous wetted contact.

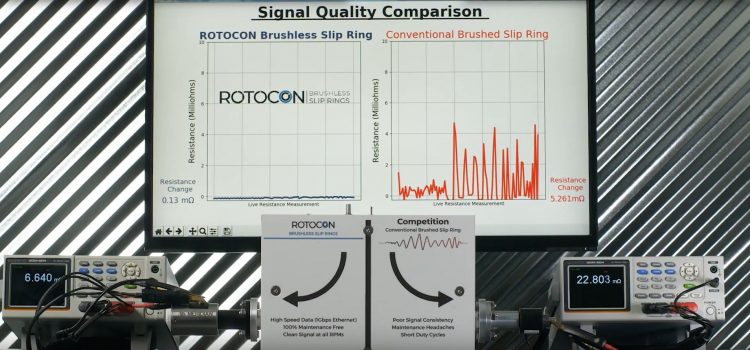

ROTOCON® brushless slip rings provide superior signal quality compared to conventional brushed slip rings. This video features high-precision MilliOhm Meters that are measuring real-time electrical resistance of each slip ring. As you can see the ROTOCON always delivers consistent results, the competition never does.

Both slip rings are spinning at the same speed, going through multiple cycles of varying speeds. The display shows the instantaneous electrical resistance of each slip ring.

Disadvantages of Conventional Brushed Slip Rings

• Noisy Signal at any RPM

• Routine Maintenance and Downtime

• Unreliable Data/Signal Transmission

• Creates Dust

Benefits of ROTOCON Brushless Slip Rings

• Perfect Signal at all RPMs

• Zero Maintenance and No Downtime

• Capable of Power and Data Communication

• Industrial Grade

Slip Ring Signal Quality Demonstration Results

The ROTOCON platform utilizes a sealed contact system that is brushless and provides the cleanest electrical signal available in any rotary electrical contact solution, for both power and data signals, you can count on no measurable noise from our rotary electrical union.

For more information, or to speak with a Meridian Laboratory engineer contact us directly. 800-837-6010