Blog / 2025.03.27

Understanding No Crush Wheels: Meridian Laboratory’s Comprehensive Deflection Data

When it comes to precision manufacturing, the smallest details can make the biggest difference in performance. That’s why selecting the right No-Crush Wheels—also known as zero crush rollers, spacer wheels, or hold down wheels—is crucial for ensuring consistent operation and optimal product handling. Whether you are designing labeling machines, packaging lines, material handling systems, or delicate conveying applications, understanding how No-Crush Wheels perform under various loads is essential.

At Meridian Laboratory, we understand that every application has unique requirements. To help our customers make informed decisions, we provide comprehensive data of how our No-Crush Wheels deflect under different loads. This guide serves as a valuable resource for engineers, designers, and production managers who need to determine the optimal wheel size and durometer (hardness) of their No-Crush Wheels, based on real-world conditions.

Real-World Applications

Our No-Crush wheels and rollers are used in a variety of industries, including:

- Packaging & Bottling – ensuring proper product spacing and gentle handling

- Paper & Printing – providing non-damaging support for delicate materials

- Converting – guiding webs and materials gently through equipment

- Automated Conveyor Systems – allowing for controlled movement of materials without excessive force

- Medical Industry – Feeding thin tubing through equipment

Why Deflection Matters

Unlike traditional solid rollers, No-Crush Wheels are designed to compress/flex under pressure or load, while maintaining the ability to return to their original shape. This unique characteristic makes them ideal for applications where maintaining product integrity and precise spacing are critical. However, choosing the wrong size or durometer can lead to inconsistent product handling, excessive wear, or even damage to your materials.

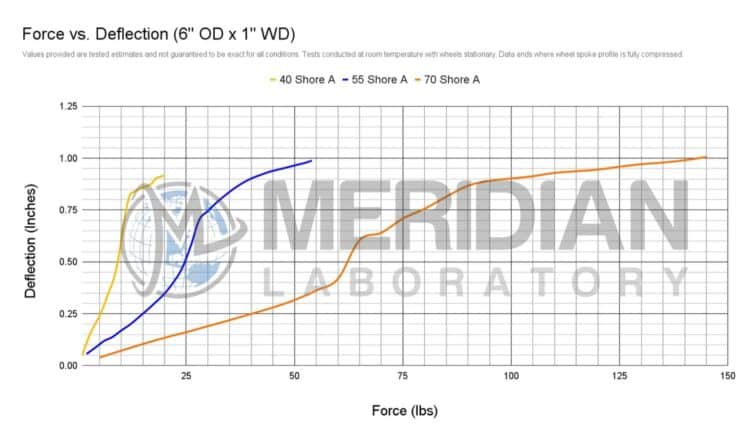

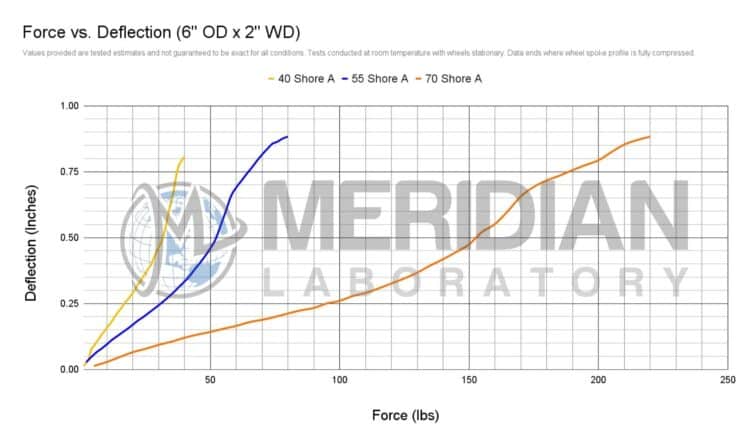

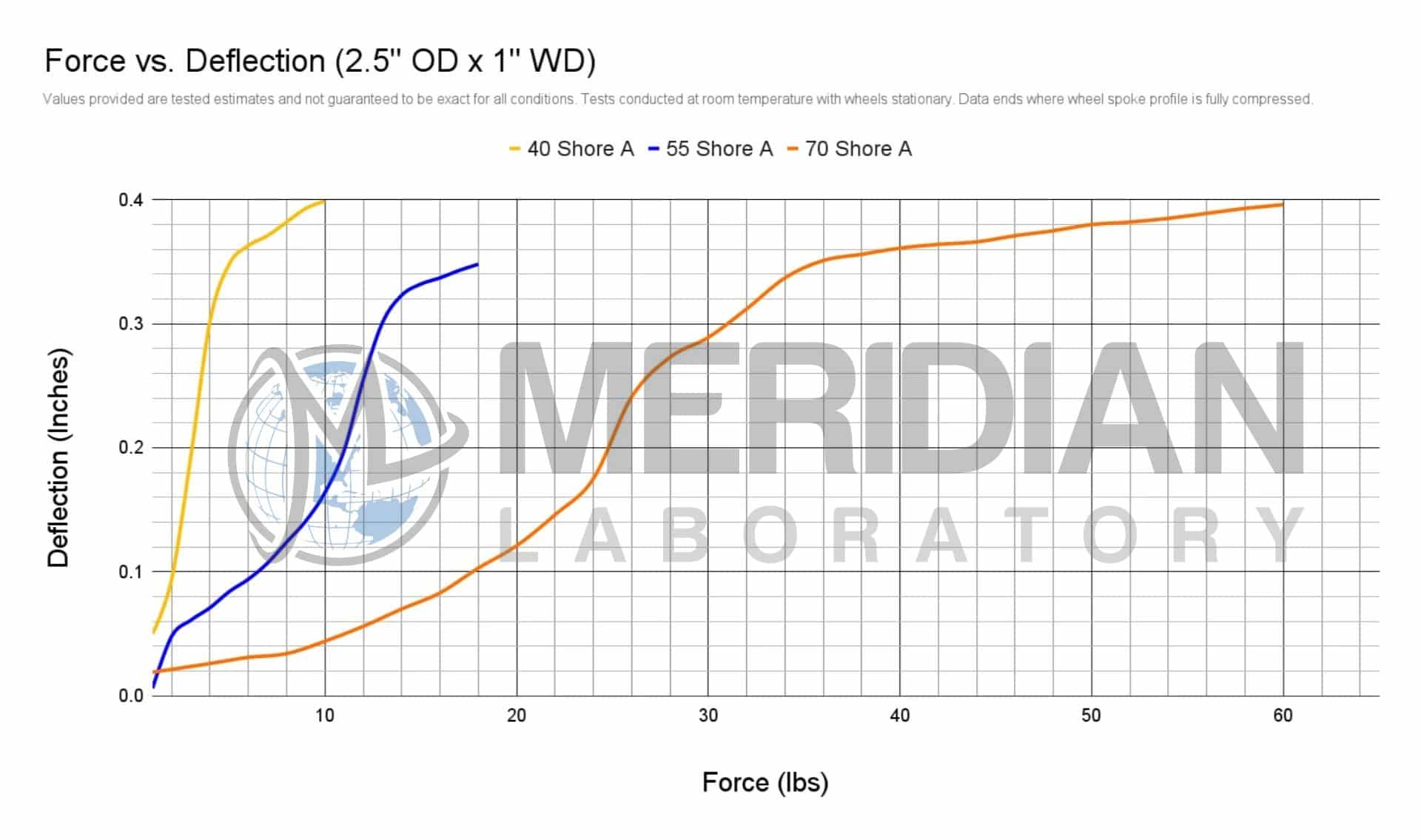

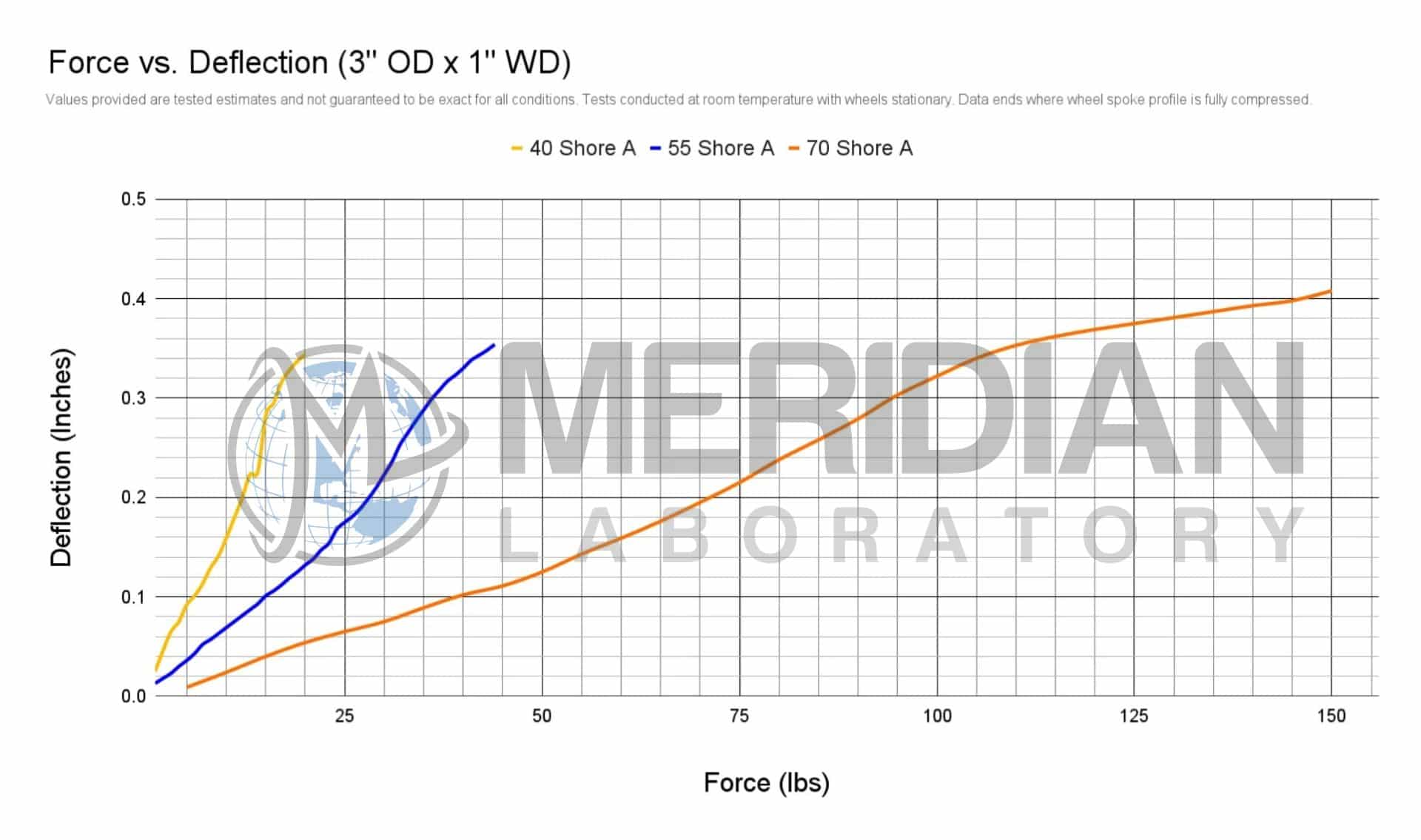

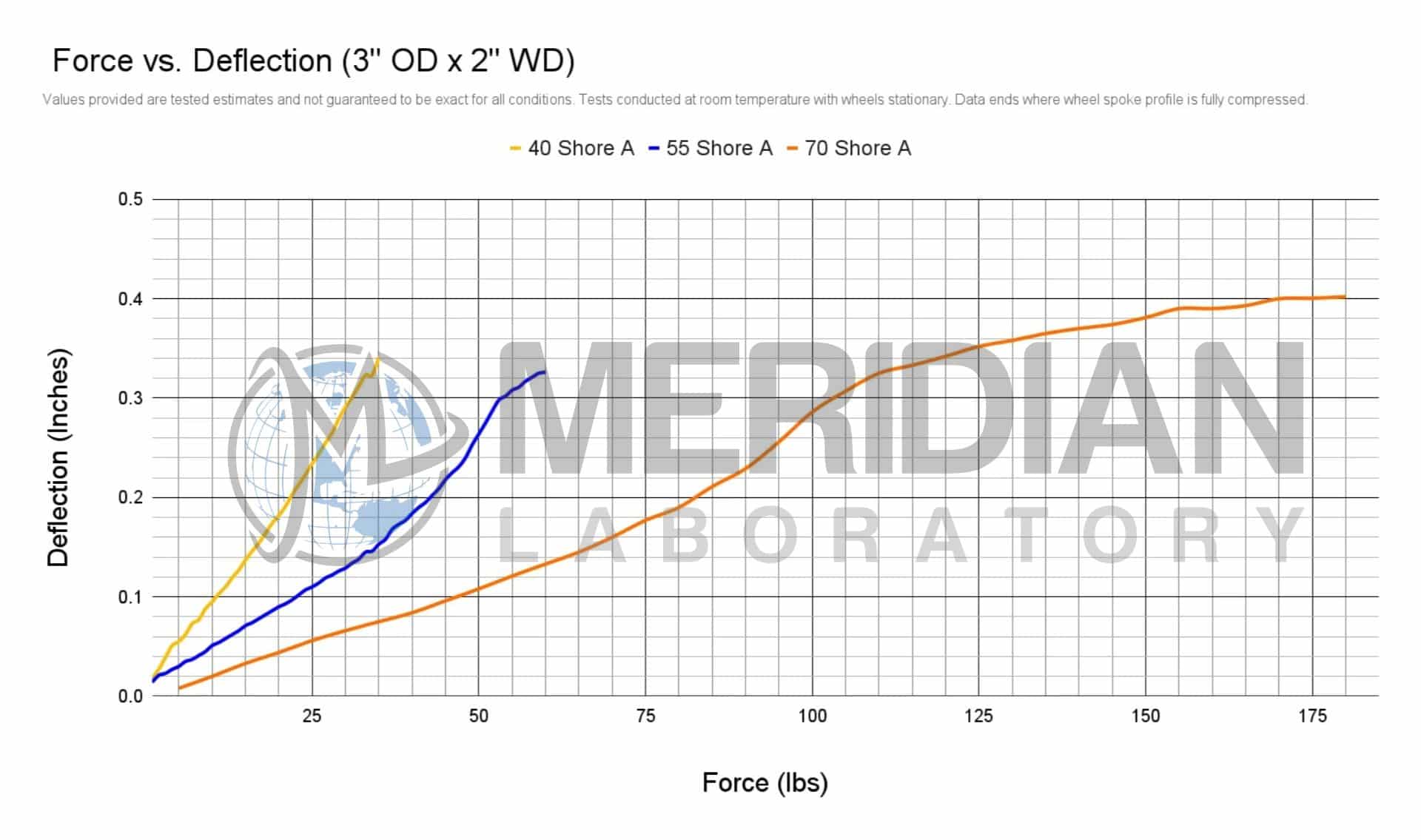

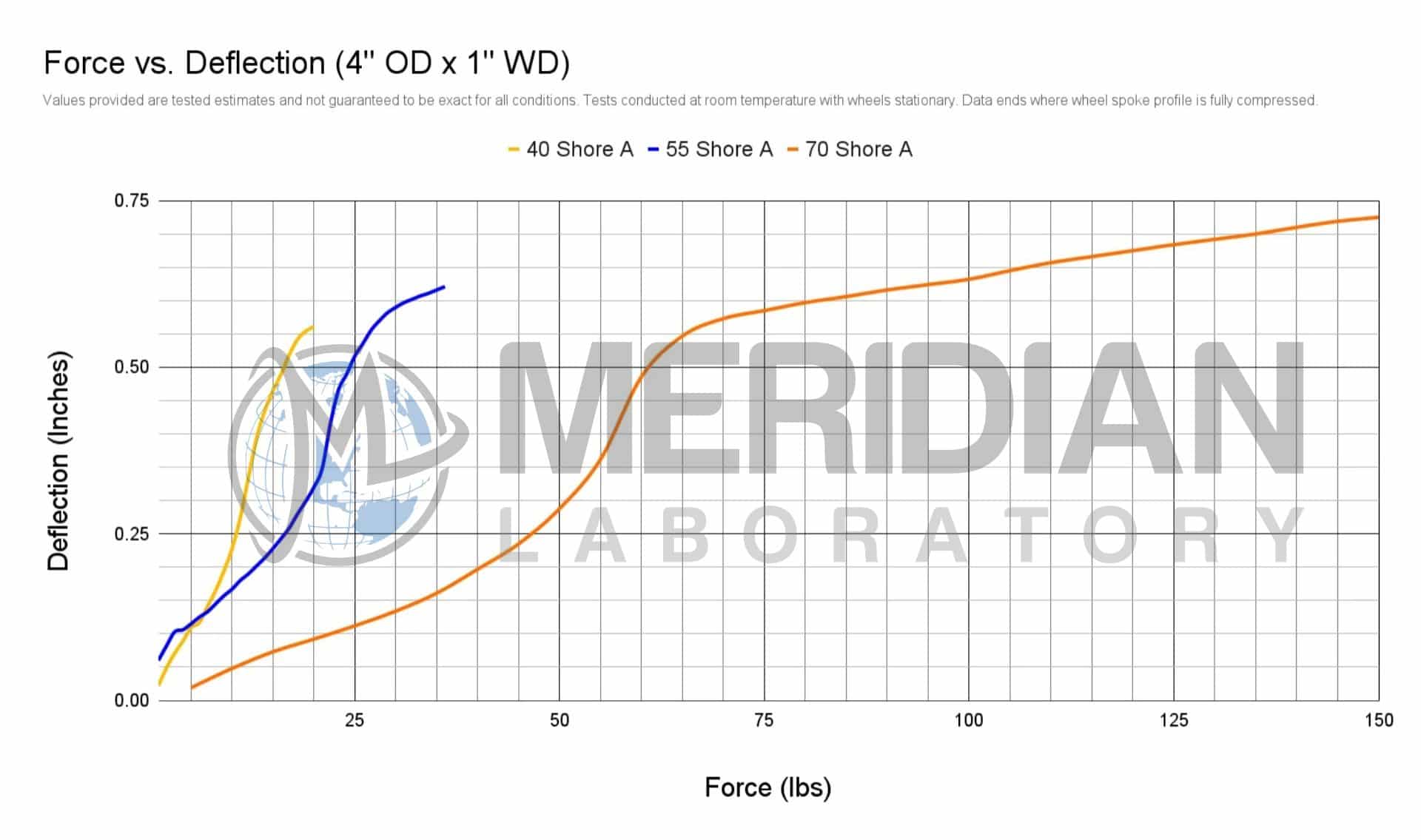

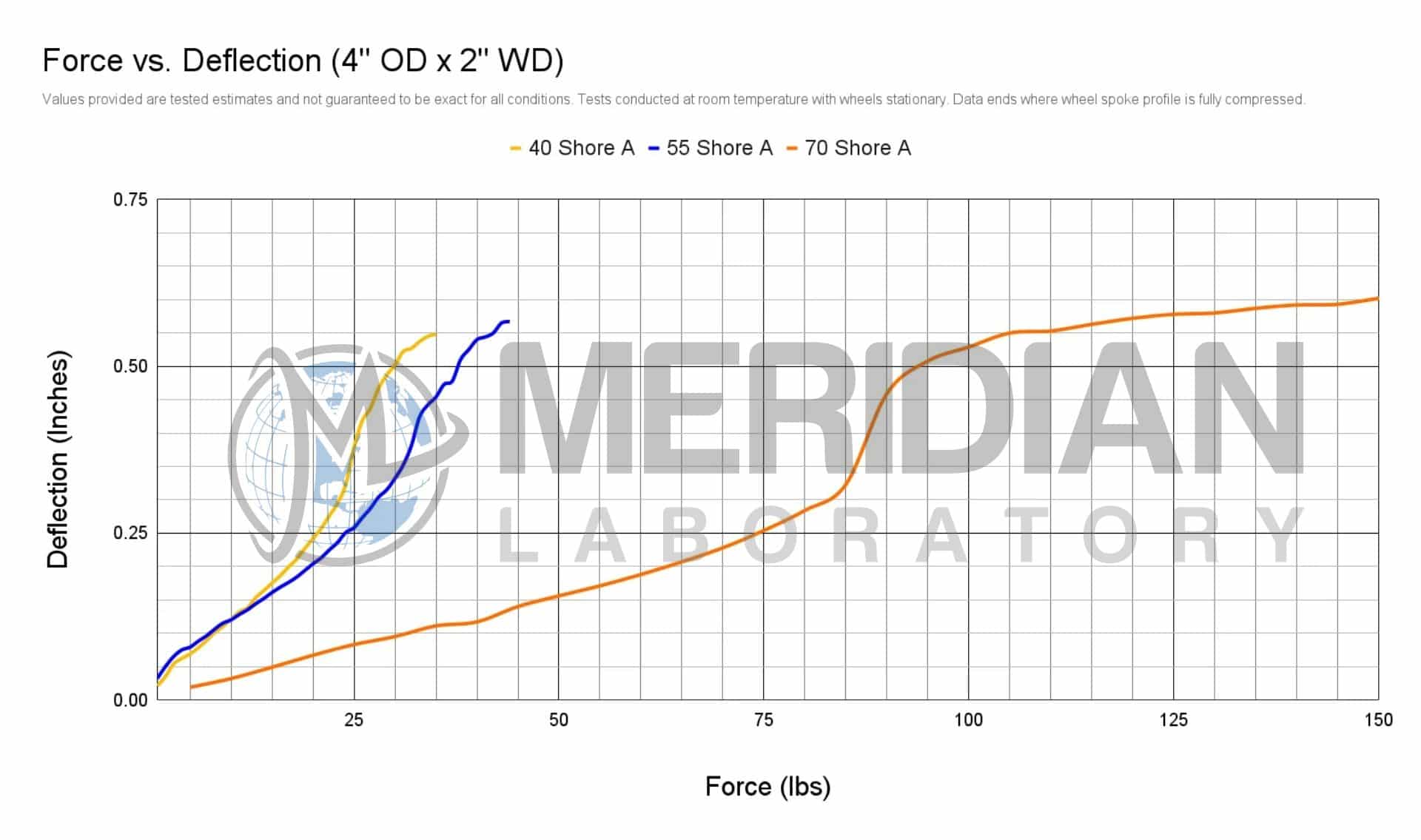

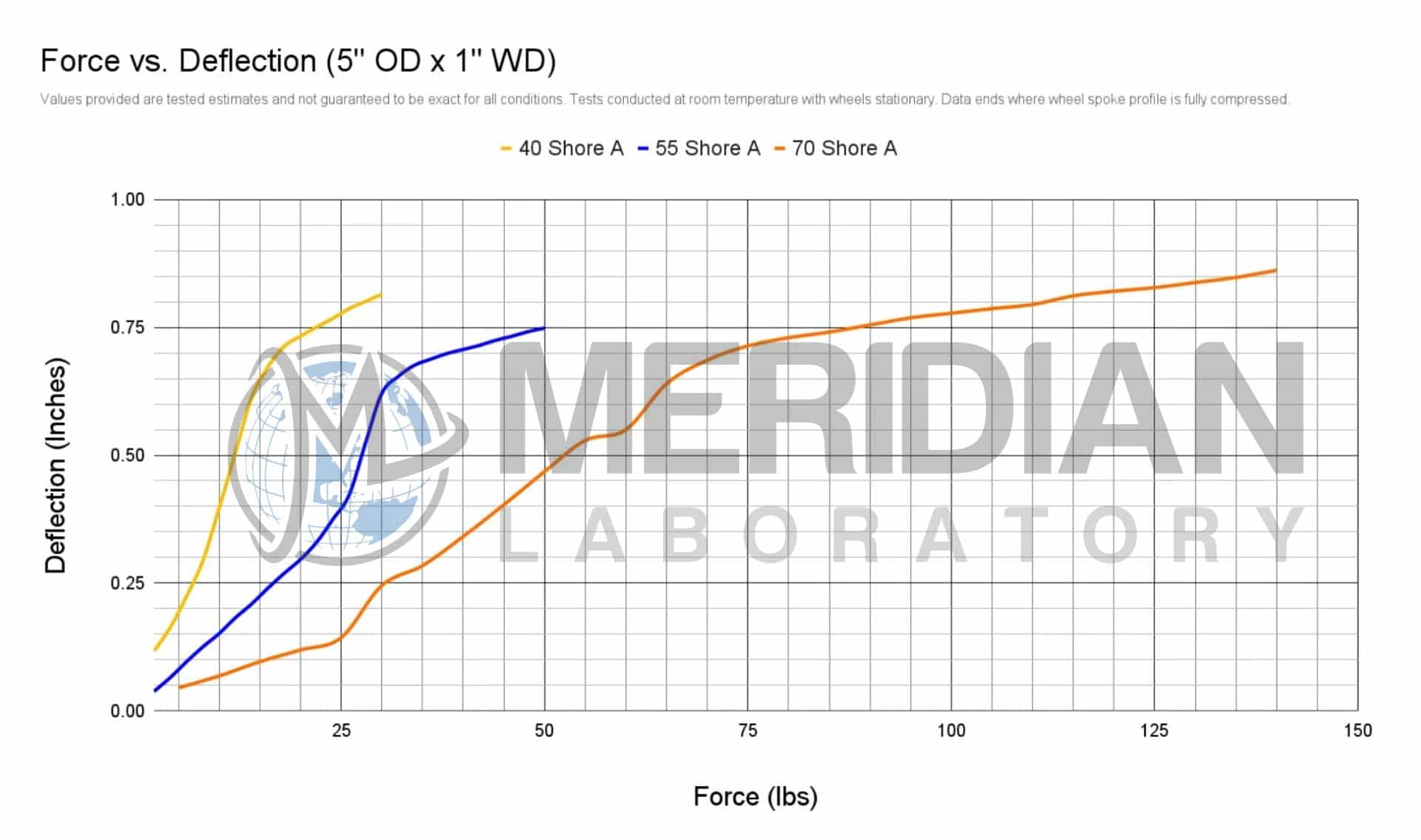

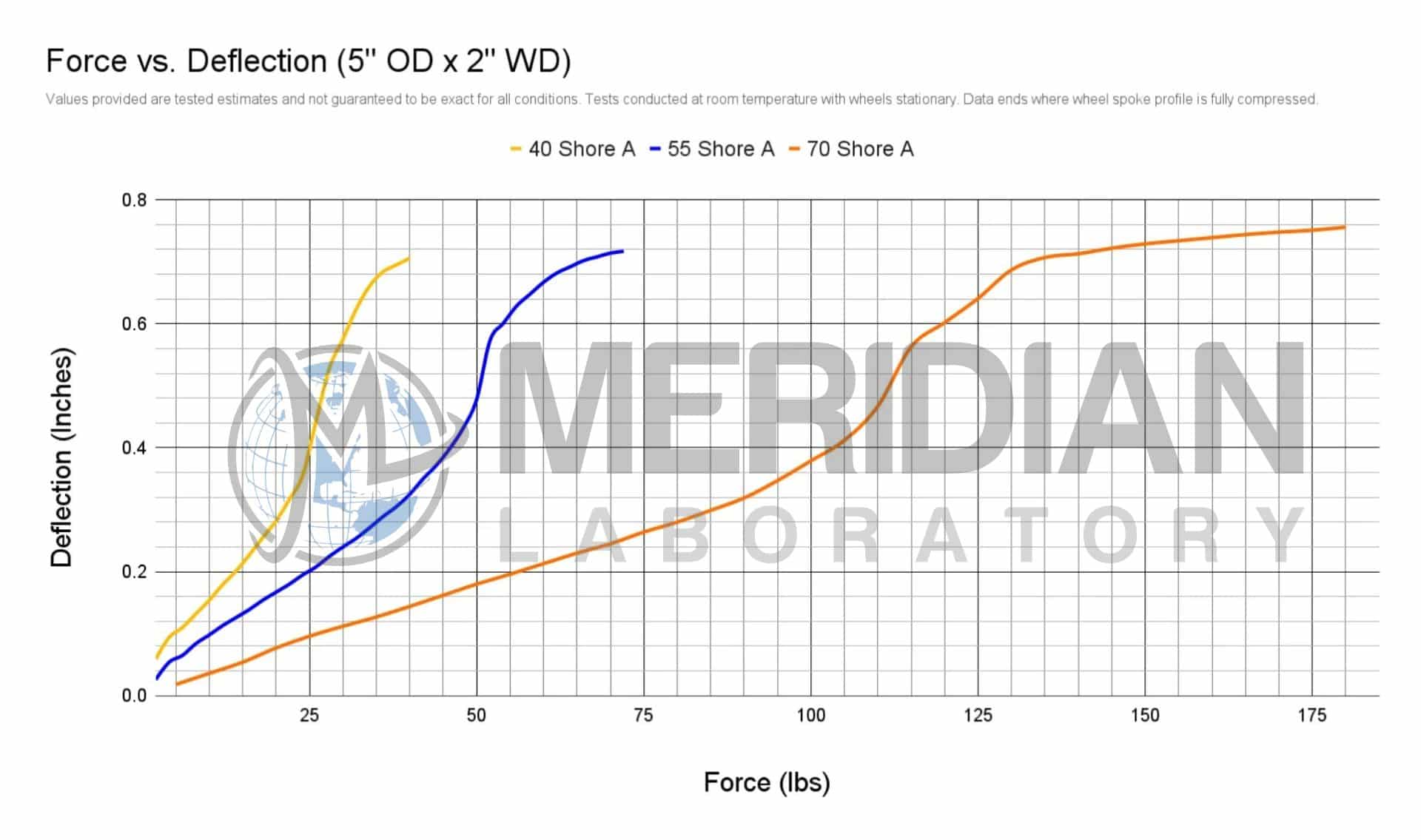

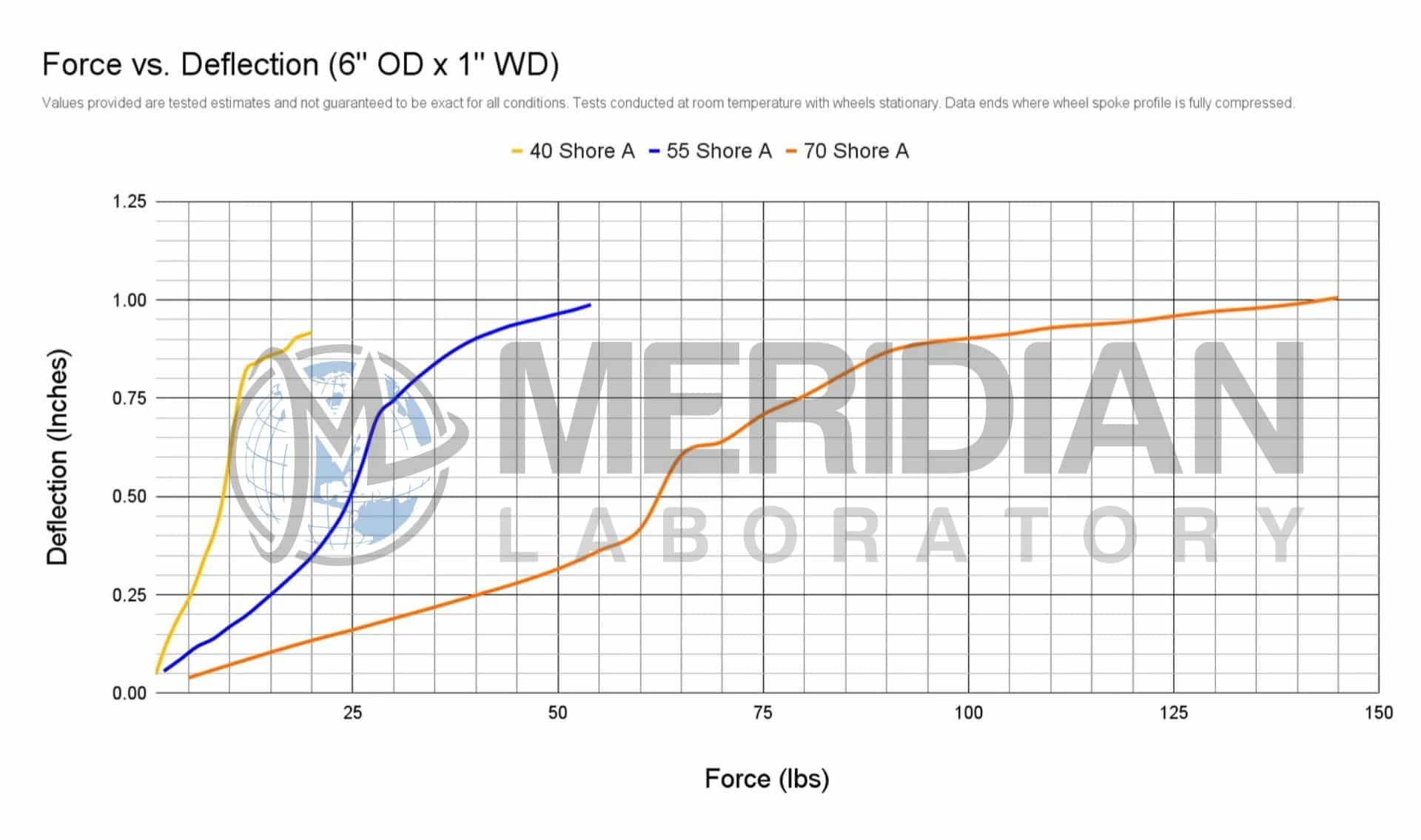

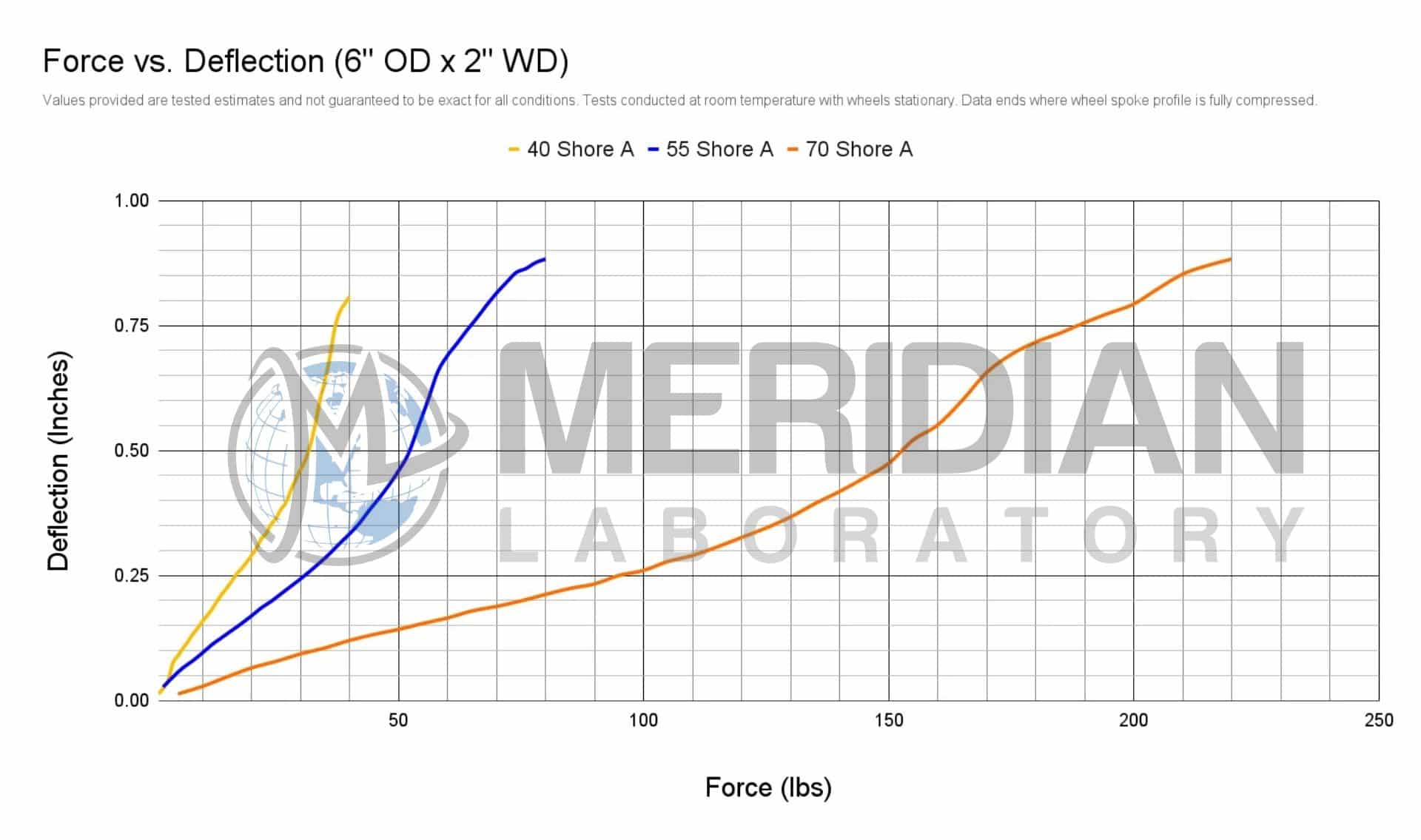

Meridian Laboratory‘s Deflection Data

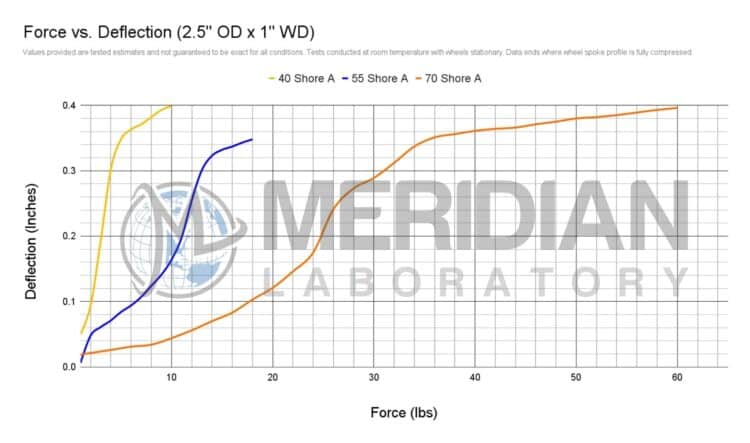

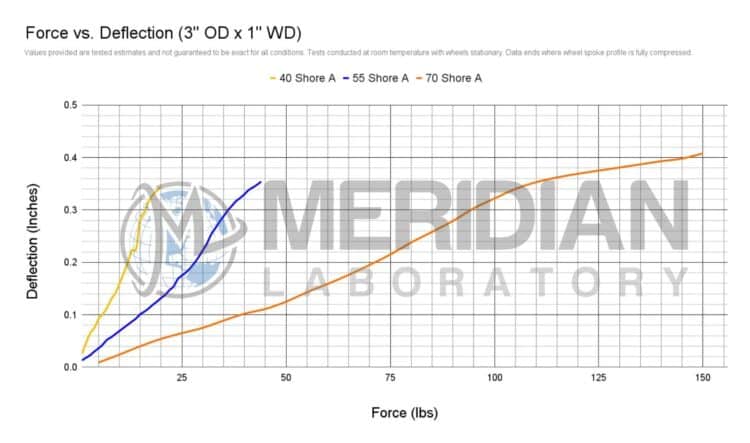

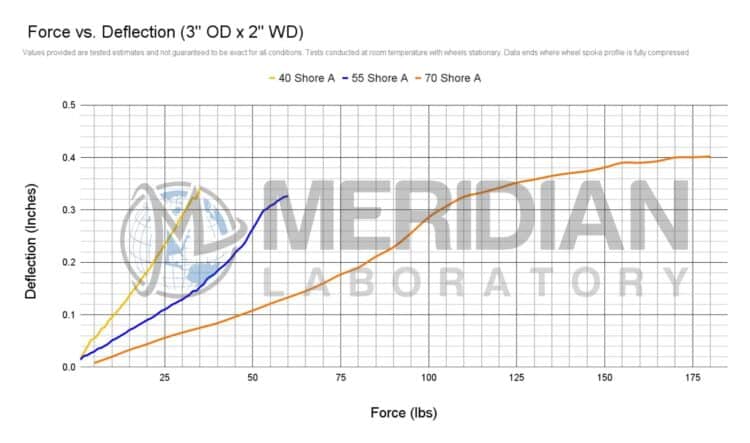

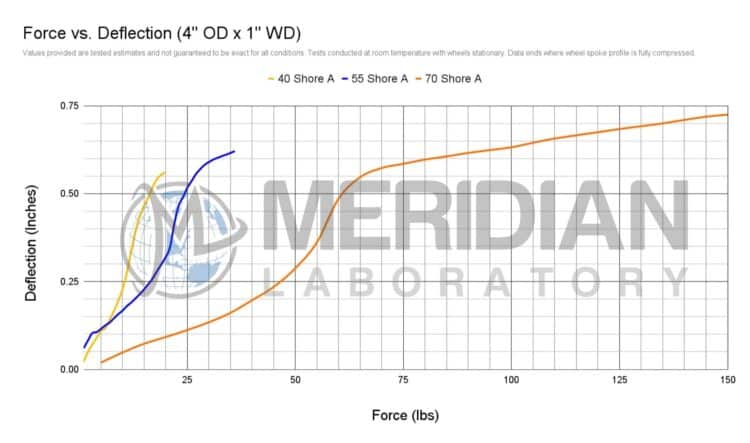

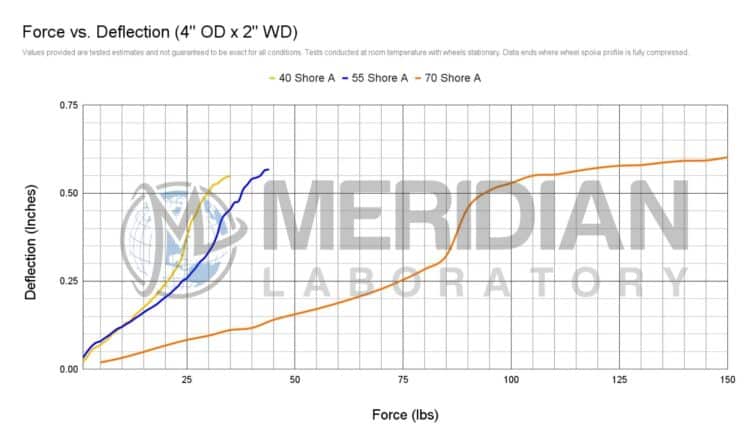

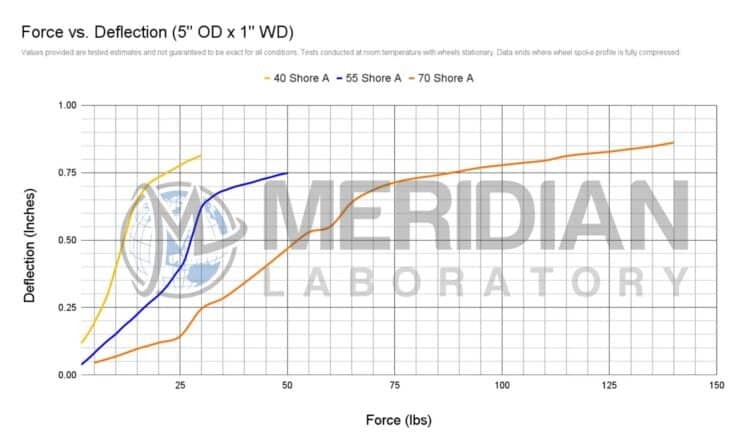

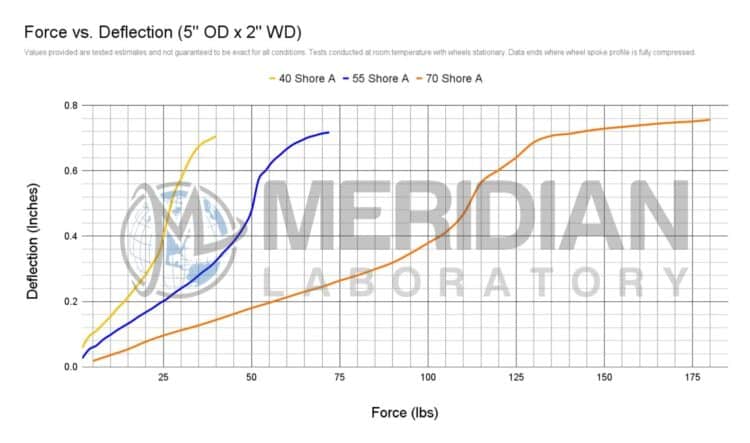

To take the guesswork out of wheel selection, Meridian Laboratory provides detailed data on how different No-Crush Wheels perform under various loads. Our guide breaks down:

- Durometer (Hardness Rating) – The relationship between size, durometer, and deflection – allowing customers to see exactly how different material hardness levels and size of wheels react under pressure. Generally speaking, as the durometer is increased, the amount of force needed to compress a wheel a given amount is also increased

- Load vs. Deflection curves – providing precise data on how each wheel compresses as the loading increases.

Using this data, customers can confidently choose the right size and durometer No Crush Wheel for their conveyor, material handling, or automated system without a time-consuming trial-and-error approach. Regardless of your industry, our deflection data will help you in selecting the perfect wheel for your application.

NO-CRUSH WHEEL DEFLECTION CHARTS

2.5″ No-Crush Wheel Deflection

3.0″ No-Crush Wheel Deflection

4.0″ No-Crush Wheel Deflection

5.0″ No-Crush Wheel Deflection

6.0″ No-Crush Wheel Deflection