Discover the ML6® Difference

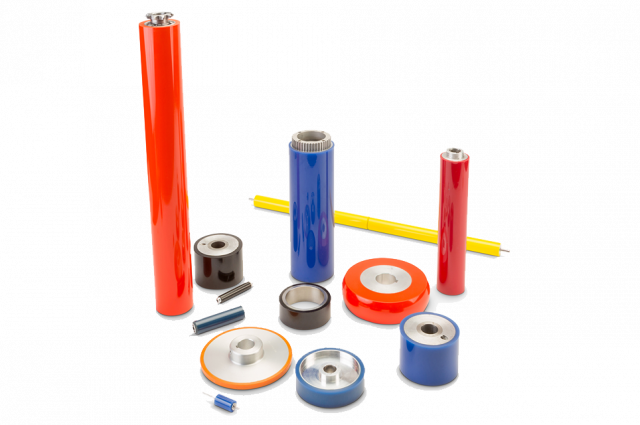

PRECISION INDUSTRIAL MOLDED POLYURETHANE PRODUCTS

What makes ML6® Polyurethane better?

- Over 55 years of precision industrial application

- Precision, finished (non-ground) surface TIR of ≤ 0.0015″

- ML6® material bonding outlives the product itself

- Standard sizing on all products – with custom modifications available at low or no cost

- Custom polyurethane development turnaround in as little as 7 days

The ML6 Polyurethane Exclusive Blend

- Long term partnerships with raw material suppliers mean stable, superior blends

- We excel at custom blends for harsh environment or heavy duty applications

- ML6® polyurethane is offered in a variety of colors and durometers (40A-90A, 75D)

- Engineered for exceptional Industrial durability from raw materials to finished product

Superior Manufacturing Techniques

- Final parts guaranteed within tolerance of up to 0.0015” T.I.R. or better

- Precision cast finished surface is not ground or cut to OD

- Closed cell surface finish provides superior friction and durability

- Our Engineers specialize in precision cast polyurethane

- The ML6® process creates exact, repeatable results, regardless of quantity, in all flat, concave, convex, notched or other profiles

ML6 Bonding Strength and Longevity

- Chemical bonding between ML6® and core material is stronger than the polyurethane itself

- Outlasts and outperforms conventional over-molded rubbers, urethanes, silicones, and nitriles

- Ability to precisely coat very intricate portions of parts to specification (within tolerance)

- Will not erode, delaminate, deflate, or mark surfaces

ML6 Standard & Custom polyurethane

- Single piece prototypes available in as little as 5 business days

- Parts become standard as soon as one piece has been manufactured

- Batch delivery of large orders available to be called in as often as daily

- Ability to batch deliver large quantities on set schedules

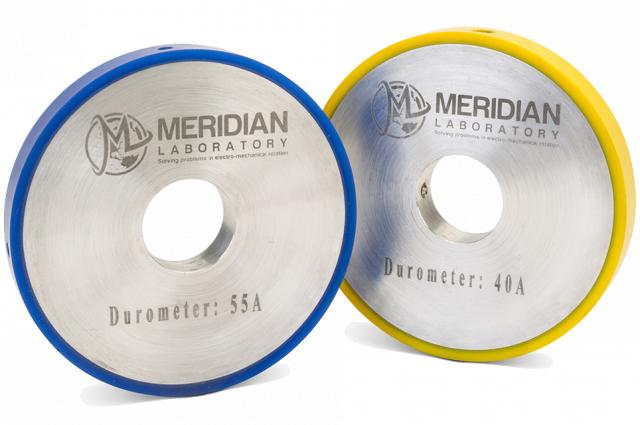

Variety of Colors and Durometers Available

- Durometers include 40A, 55A, 70A, 80A, 90A, and 75D (Shore Hardness Scale)

- Colors include yellow, blue, orange, black, red, white, green, and clear (with custom options available)

- Ability to change color and durometer without setup or change cost

- We excel at helping you match durometer and material thickness to your specific application

Meridian Laboratory’s Engineering Experience

- Experience in delivering precision polyurethane solutions since 1963

- Experience partnering with small, niche operations, and multinational corporations alike

- Welcoming and receptive to new and complex engineering challenges

- Deep experience in engineering polyurethane solutions across a broad spectrum of industries and applications