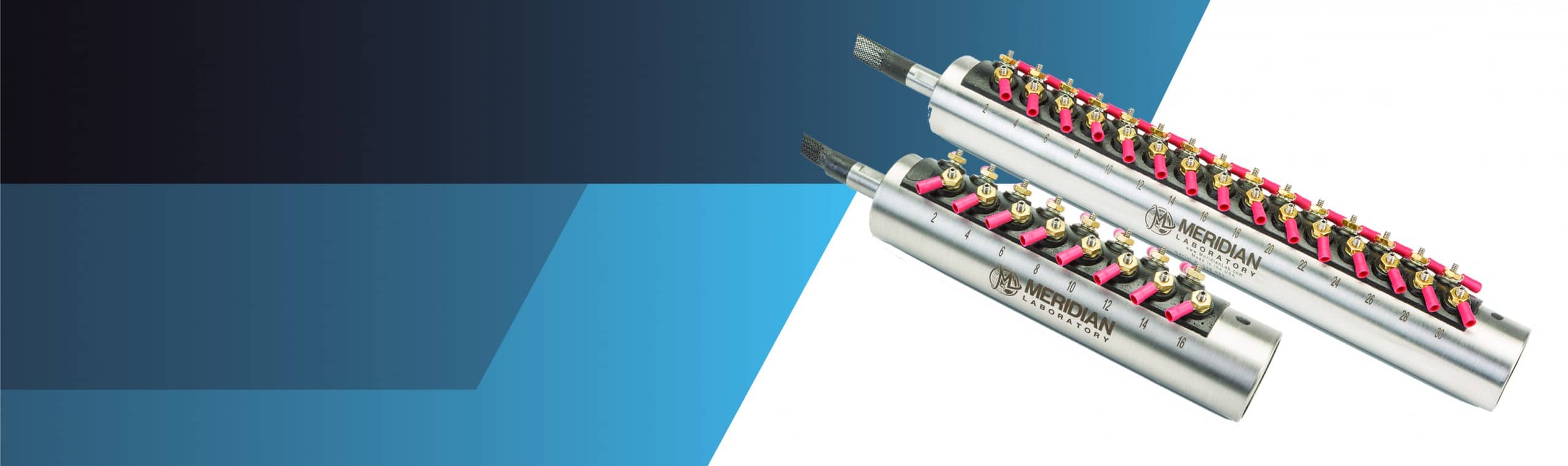

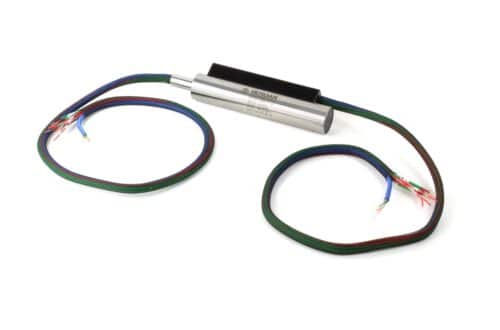

Meridian Laboratories can integrate virtually any single or combination of wiring configurations in its ROTOCON custom slip rings. Most standard ROTOCON units are specified with MIL-W-16878 nickel plated, stranded copper wire with Teflon insulation. Depending on your application and specifications, we can accommodate the following wire/cable types:

- Single stranded cables

- Multi stranded cables

- CAT5 / CAT5e / CAT6 / CAT6e cables

- Coaxial cables

- Heater (fiberglass shielded) cables

- Strain gage cables

- Shielded cables

- Thermocouples wires (all types)

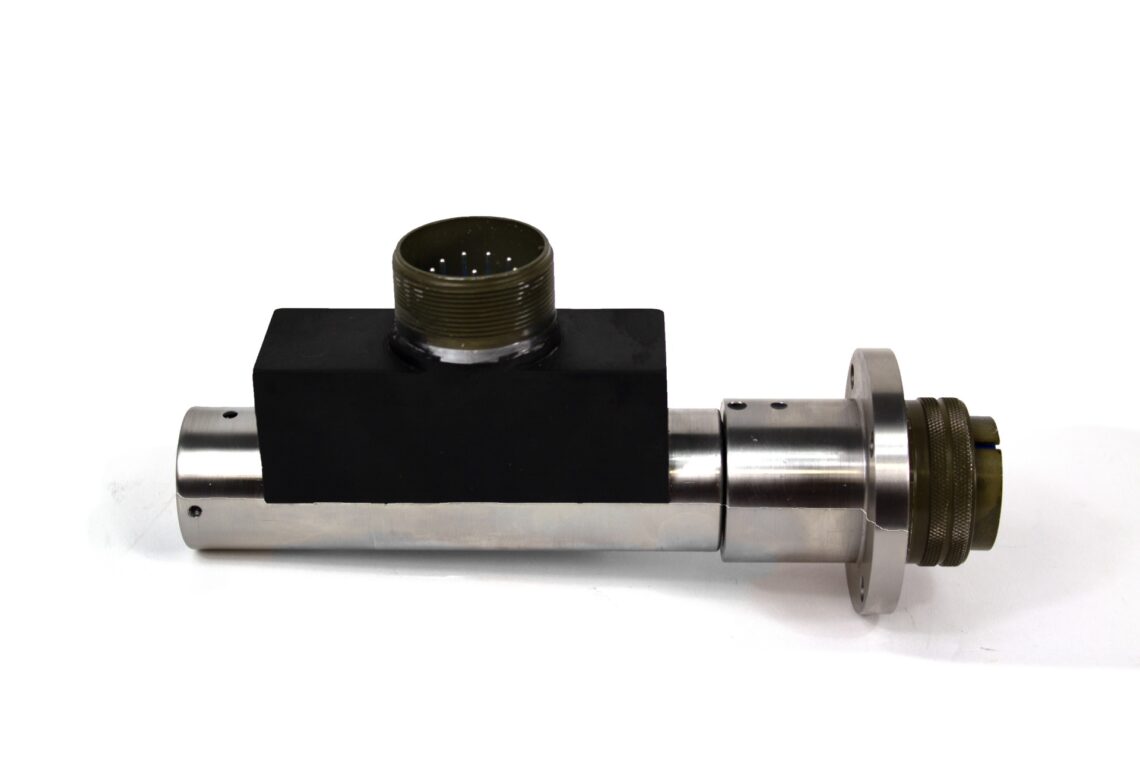

Meridian Laboratory has various mechanical mounting styles available to best integrate with your design or fit with existing equipment. We offer, but are not limited to:

- End-of-shaft mounting

- Through-hole mounting

- Double end of shaft mounting

- Housing mounting

- Flange mounting

- Base mounting

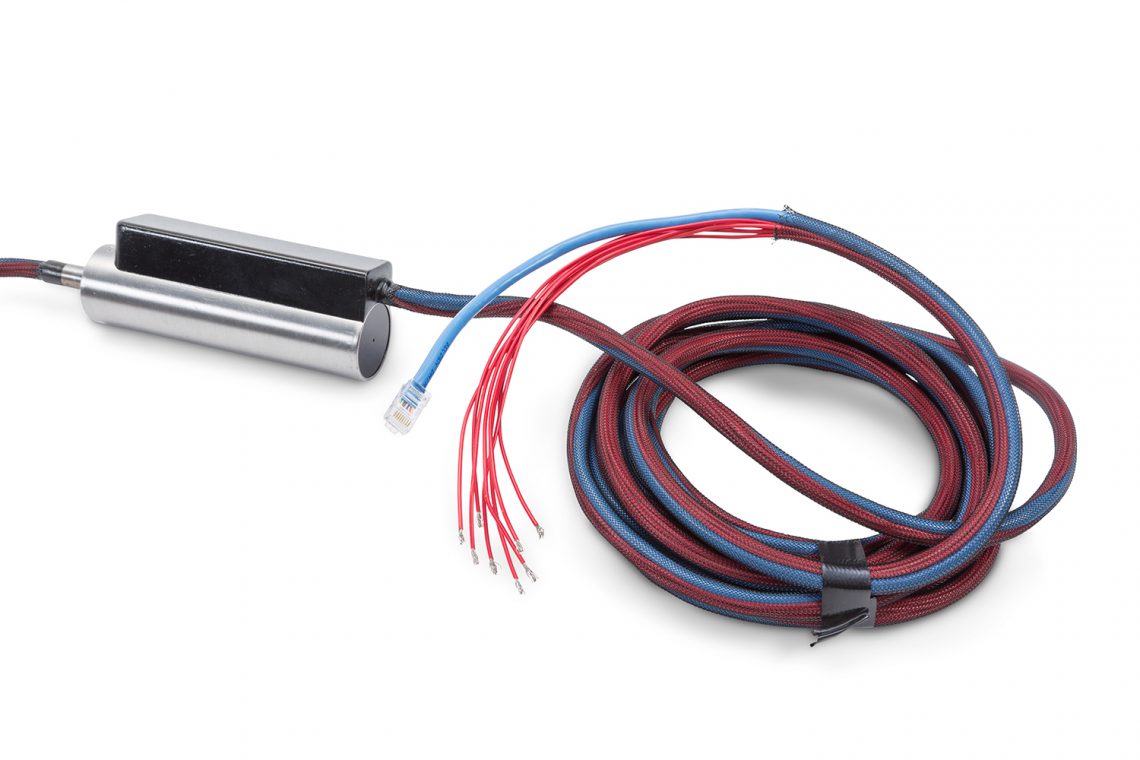

Meridian Laboratory offers different electrical termination options to best fit your application or usage requirements. We offer standard, but are not limited to:

- Ring terminals

- Potted flying leads (virtually any manufacturer of wire)

- Circular / MIL-spec connectors (Amphenol, Cannon, Phoenix, Turck, TE, and others)

- Coax connectors (all frames and sizes)

- Wet-mateable connectors (Teledyne, Seacon, TE, Burton/Cooper, SubConn, Impulse, Mecca, Marshall Underwater, and many others)

Meridian Laboratory is able to deliver standard and custom slip ring assemblies with sealing capabilities up to IP68. Meridian Laboratory ROTOCON brushless slip rings are extremely robust and built to handle the most demanding environments and applications.

For applications which operate in elevated temperature environments, or which may drive a ROTOCON brushless slip ring past their rated operating temperatures, we offer custom air and water cooling solutions.

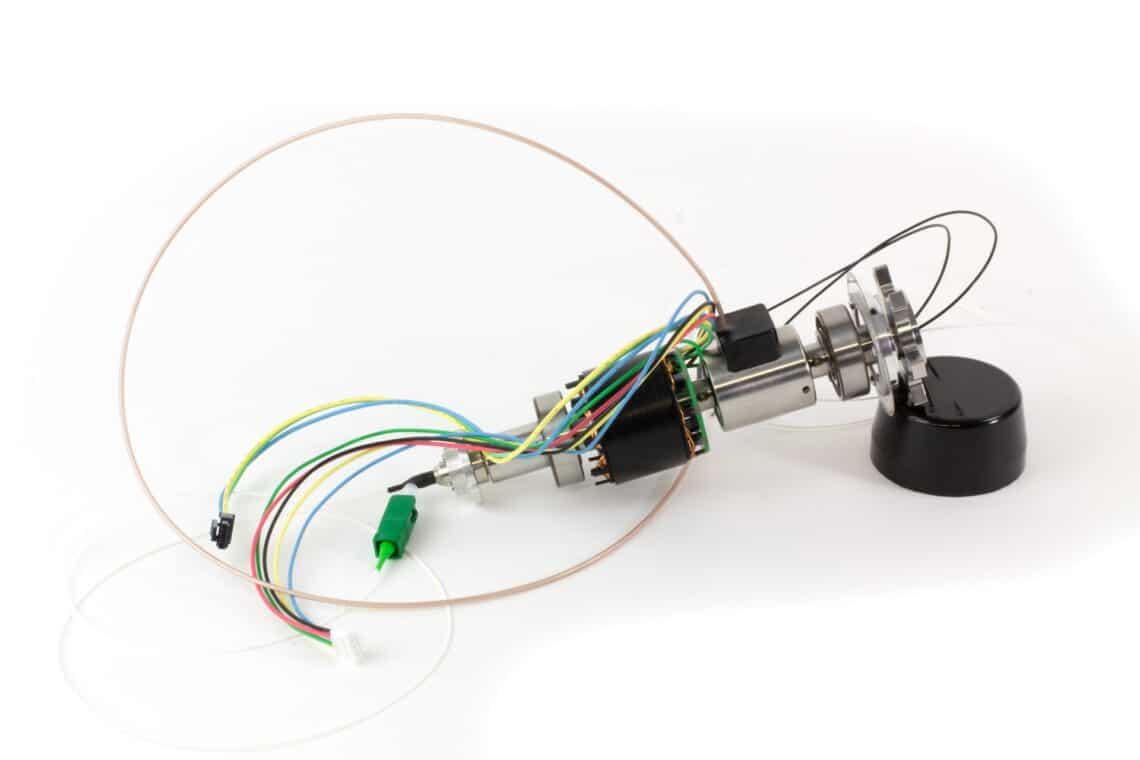

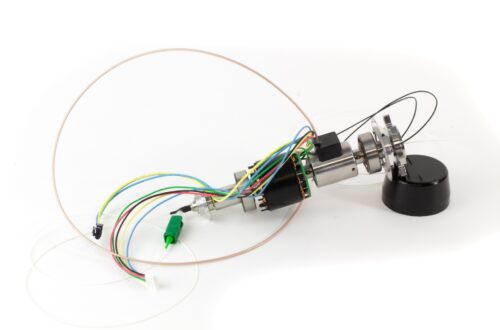

Fiber-Optic Rotary Joint Integration: Meridian Laboratory offers a full suite of single and multi-channel fiber optic rotary joints integrations. Offered in a wide variety of configuration options for varying size, wavelength, environmental, material, and termination requirements, we are your single-source provider for slip ring and FORJ solutions. See our full list of capabilities and solutions.

| FIBER TYPES | Single-mode E9/125μm Multi-mode G50/125 μm Multi-mode G62.5/125 μm *Fiber protection available |

| CHANNELS | Standard: 1, 2, 3-20 Channels Custom: Up to 81 Channels |

| CONNECTOR TYPE | SC, LC, FC, ST, LSA, Molex/LC, LuxCis |

| POLISH | UPC, APC, PC |

| DIGITAL DATA TRANSMISSION | Up to 40Gbits/s per channel |

| RPM | Up to 3,000 RPM (Model specific) |

| TEMPERATURE | -40F to 185F |

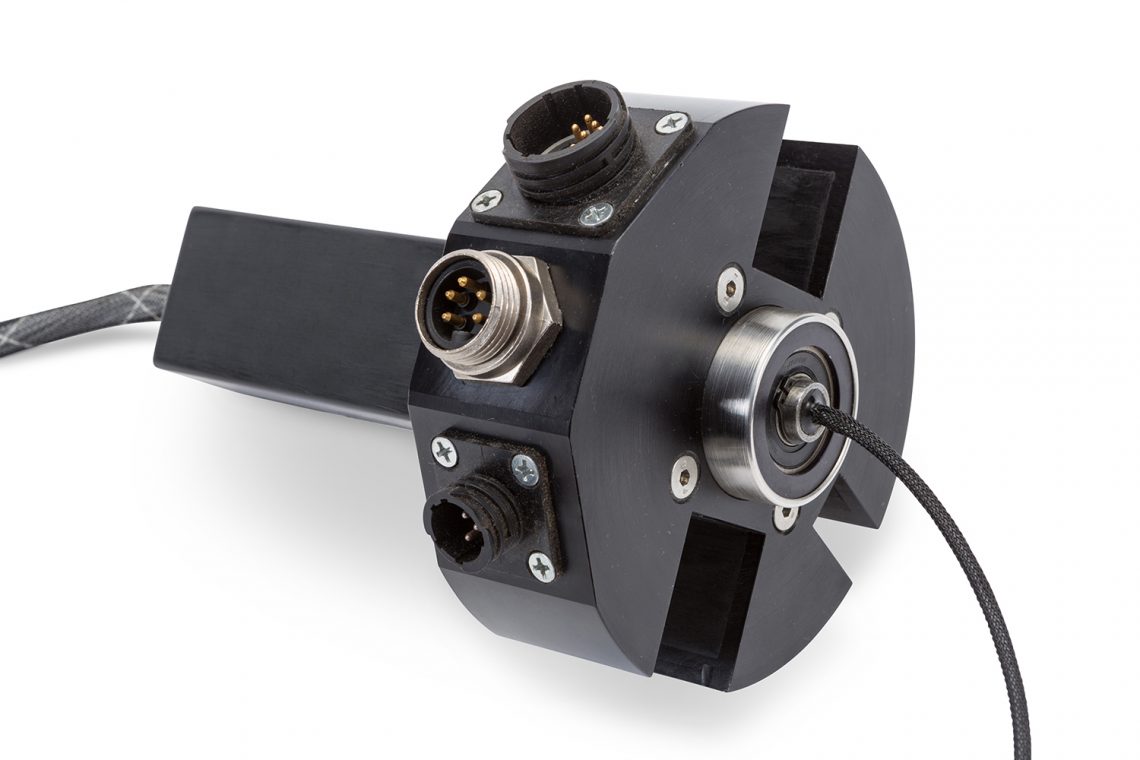

Rotary Union Integration: Meridian Laboratory offers customized solutions which include single and multi-passage rotary unions to pass fluids, gases, and other medias. See our full list of capabilities and solutions.

| RPM | Up to 15,000 RPM |

| MOUNTING | Through-hole, end of shaft, or flange mount available |

| HOUSING | 6061 Aluminum or 304 Stainless steel |

| PASSAGES | Up to 20 Passages |

| PRESSURE | Up to 23,000 PSI - speed and media dependent |

| TEMPERATURE | -321F to 900F, depending on options |