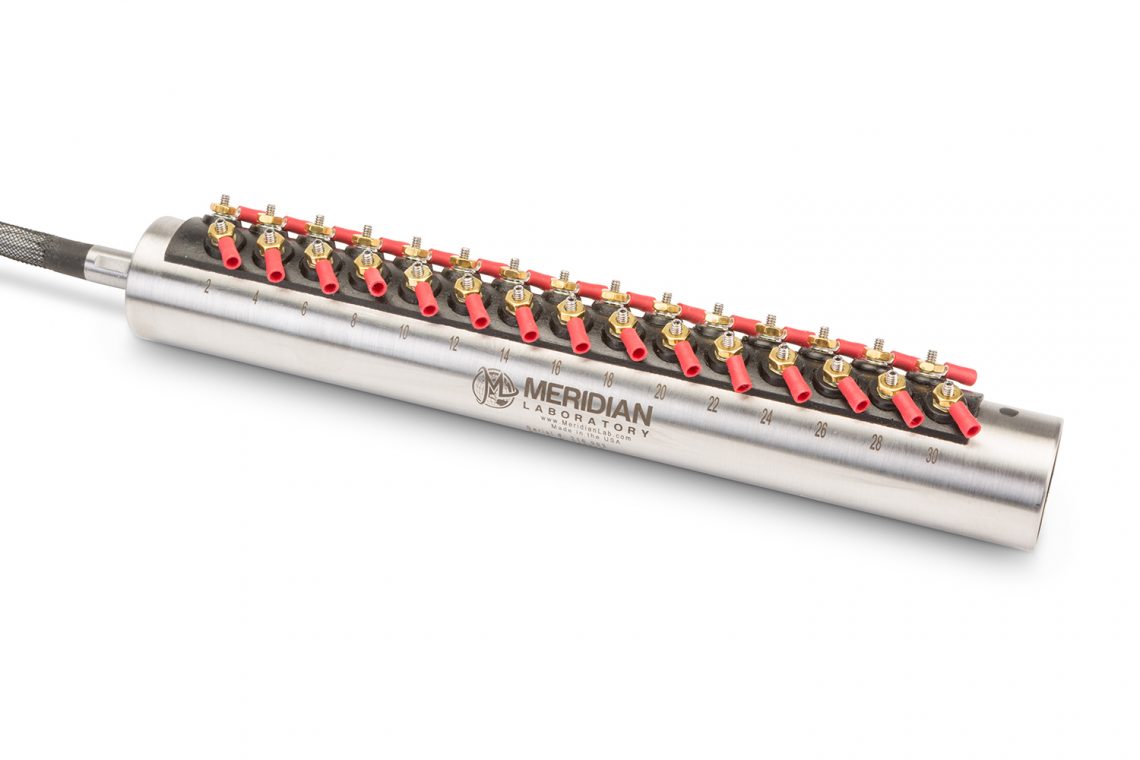

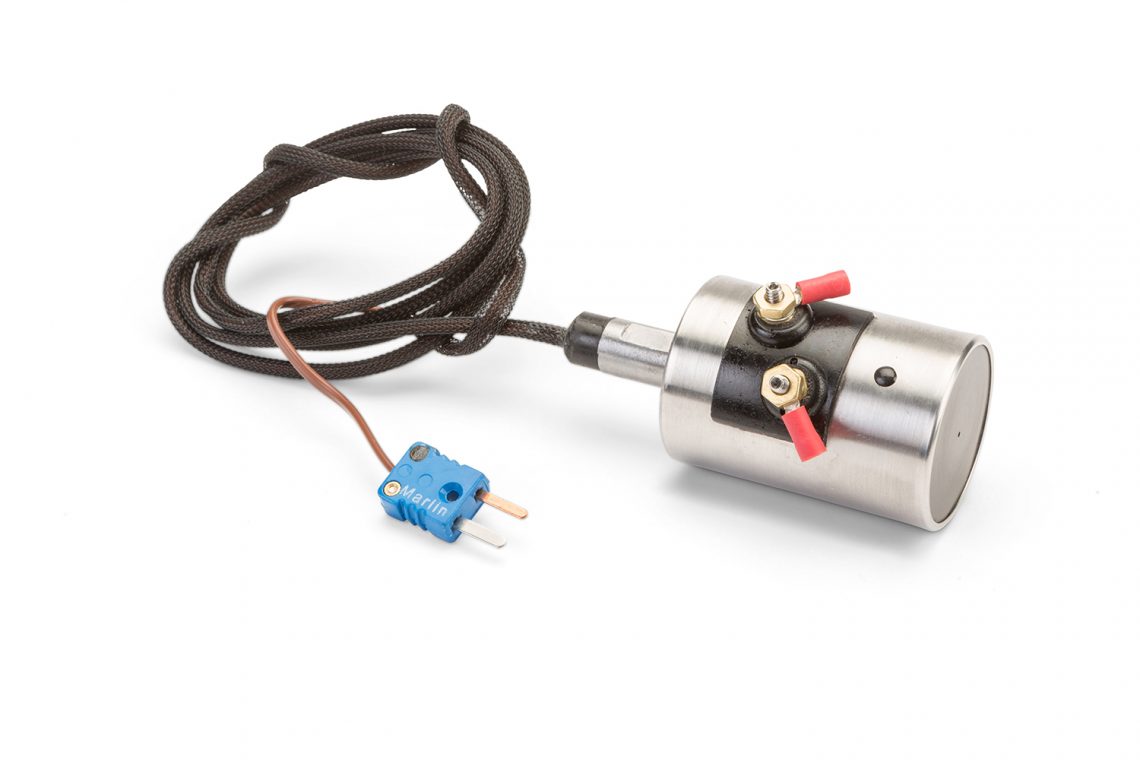

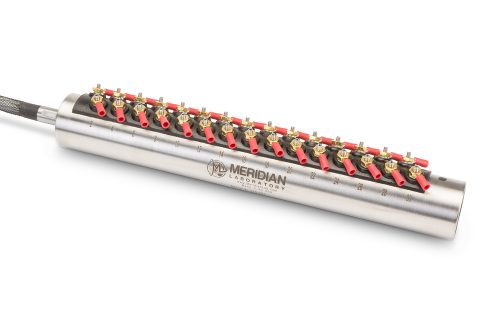

| RPM | Model dependent, see model specifications |

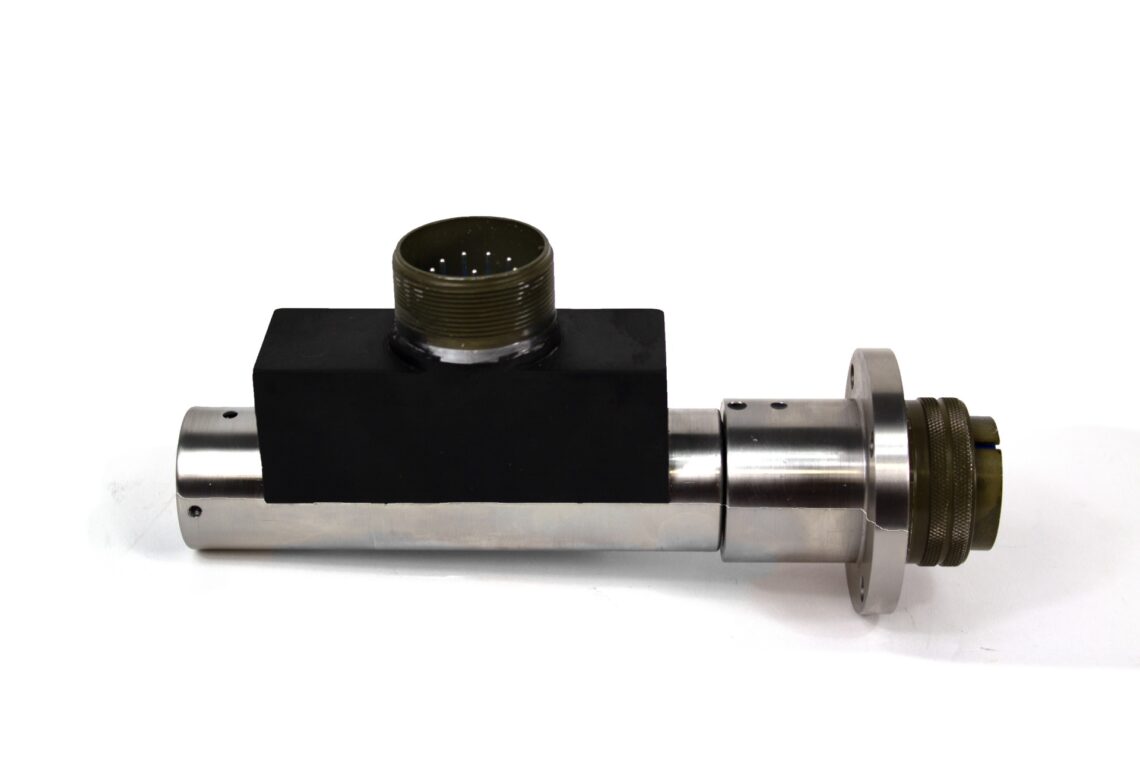

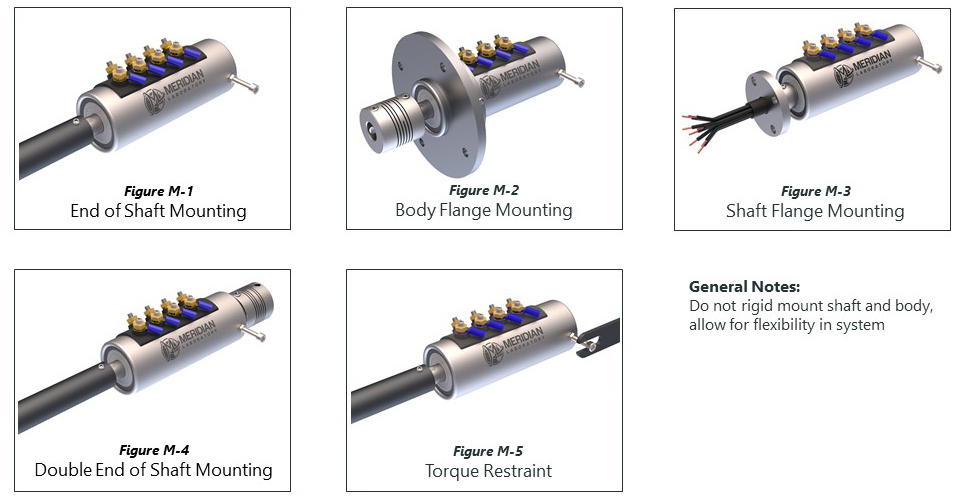

| MOUNTING | End of shaft or flange (Click here for installation and best practices video.) |

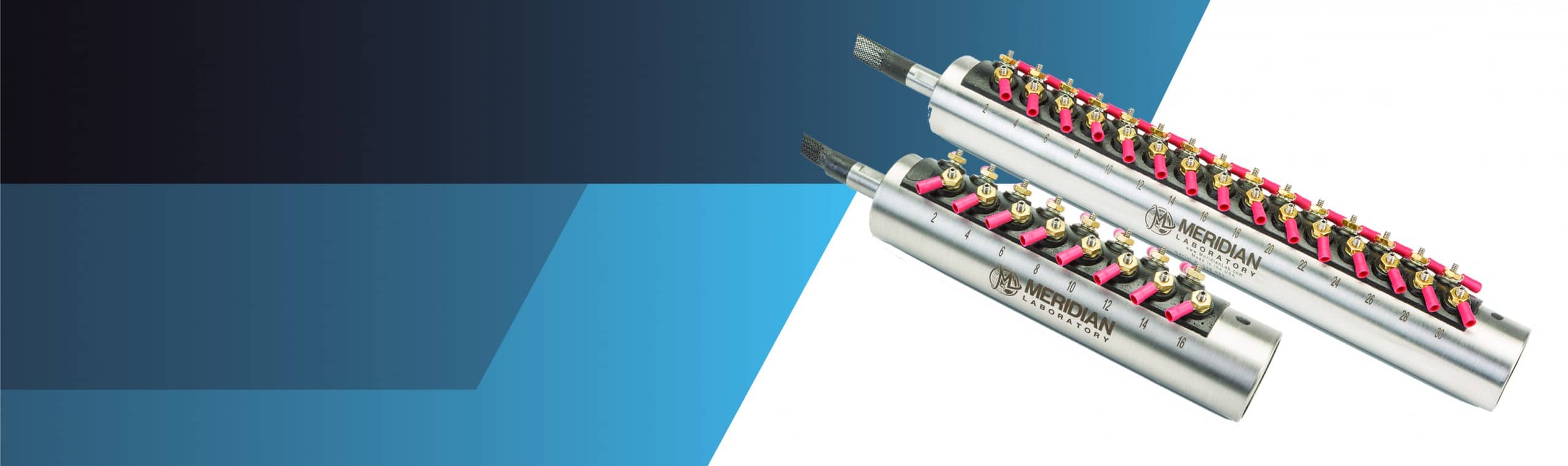

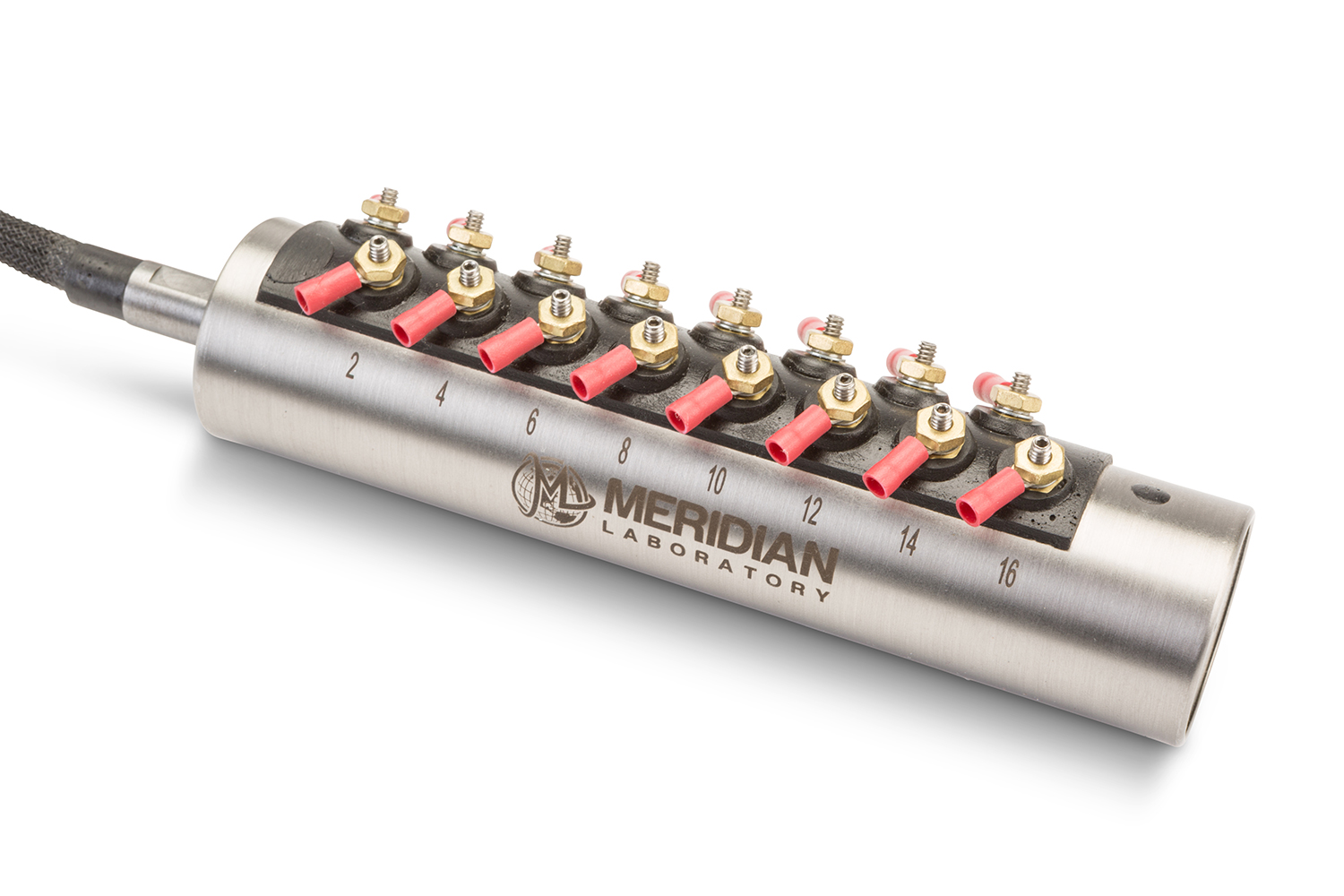

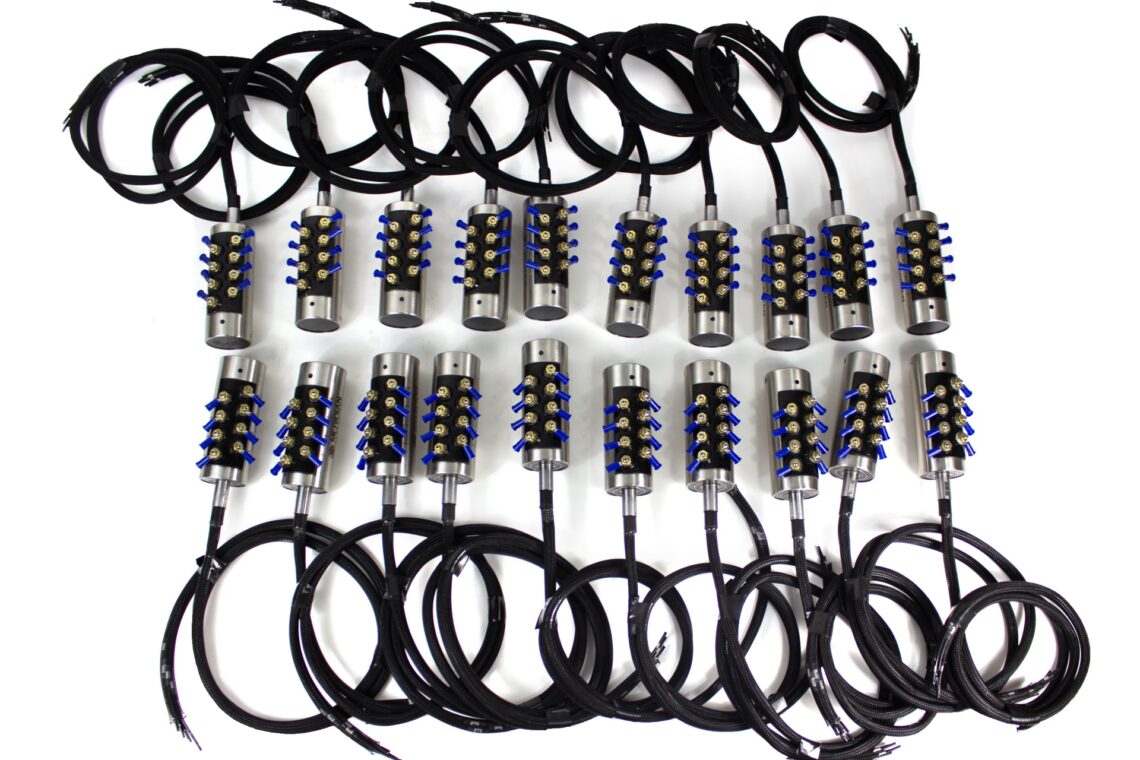

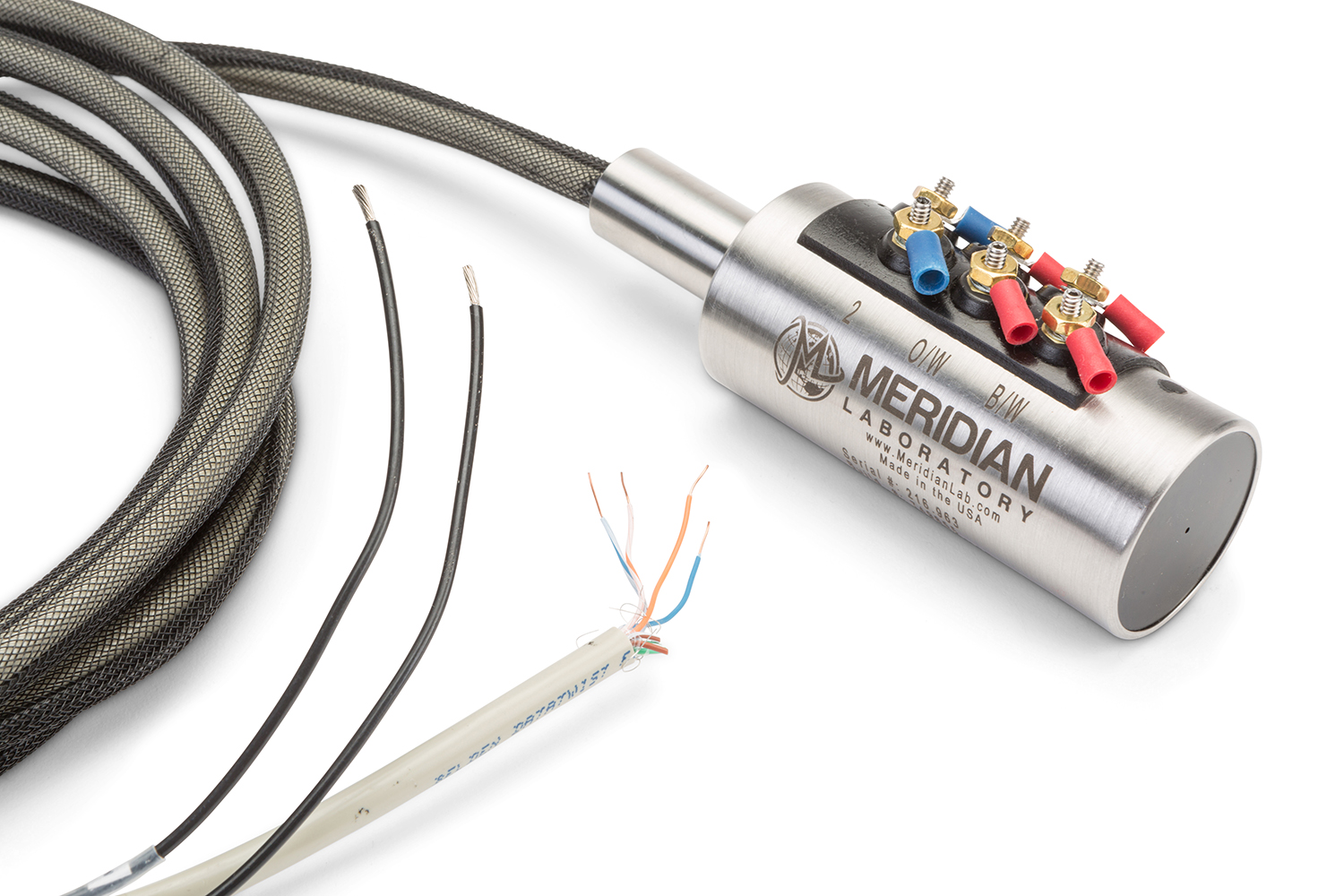

| HOUSING MATERIAL | 304 Stainless steel |

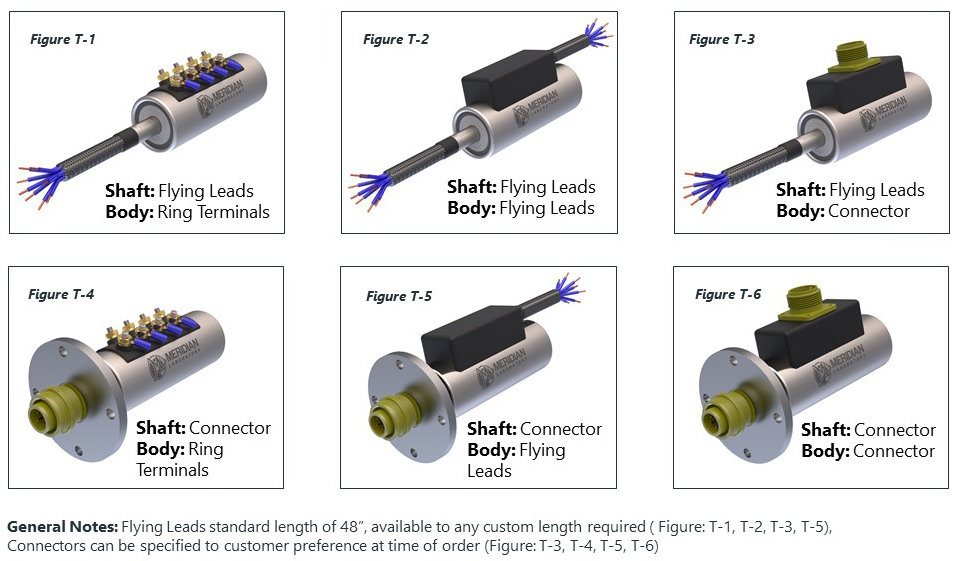

| TERMINATIONS | Ring terminals, flying leads, MIL-spec or other connectors |

| OPERATION | Can be operated in any direction or orientation |

| MAINTENANCE | Features permanently lubricated bearings, brush-free design requires no user maintenance |

| VOLTAGE | Standard: Up to 600V AC/DC, Optional: Up to 3,500V AC/DC |

| MINIMUM INSULATION RESISTANCE | >500MΩ @ 1kVDC |

| AMPERAGE | Model dependent, up to 35A/channel (channels can be bridged in parallel, for higher capacity) |

| FREQUENCY | Up to 1GHz (Model and application dependent) |

| DATA & SIGNAL TRANSMISSION | Ethernet (10/100/1000Mbps), Etherlink, LAPPNET, Profinet, Profibus, ControlNet, DeviceNet, CAN-Bus, RS485, RS432, RS422, USB (1.0/2.0), Modbus, EtherCAT, CC-Link, coax, thermocouple (all types) and all other major communication protocols (With an appropriate number of circuits and cables) |

| STATIONARY CONTACT RESISTANCE | <0.1mΩ |

| ROTATING CONTACT RESISTANCE (0-MAX RPM) | Same as stationary contact resistance (<0.1mΩ) |

| ELECTRICAL NOISE | <0.01uV |

| NOTES | Intrinsically immune to internal arcing, designed for continuous operation |

| AMBIENT TEMPERATURE | Not to exceed 160˚F (70˚C) |

| IP RATING | Available up to IP67 |

| RPM | Up to 15,000 RPM |

| MOUNTING | Through-hole, end of shaft, or flange mount available |

| HOUSING | 6061 Aluminum or 304 Stainless steel |

| PASSAGES | Up to 20 Passages |

| PRESSURE | Up to 23,000 PSI - speed and media dependent |

| TEMPERATURE | -321F to 900F, depending on options |

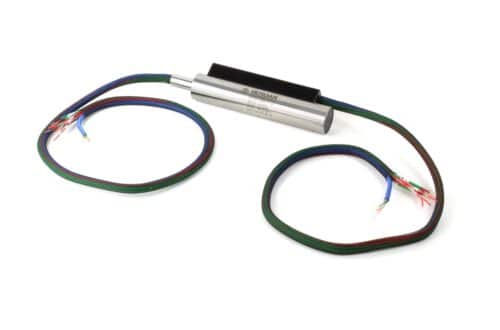

| FIBER TYPES | Single-mode E9/125μm Multi-mode G50/125 μm Multi-mode G62.5/125 μm *Fiber protection available |

| CHANNELS | Standard: 1, 2, 3-20 Channels Custom: Up to 81 Channels |

| CONNECTOR TYPE | SC, LC, FC, ST, LSA, Molex/LC, LuxCis |

| POLISH | UPC, APC, PC |

| DIGITAL DATA TRANSMISSION | Up to 40Gbits/s per channel |

| RPM | Up to 3,000 RPM (Model specific) |

| TEMPERATURE | -40F to 185F |