ROTOCON High-Performance Brushless Slip Ring Solutions

| » Provides brush-free design requiring no user maintenance | » Delivers clean electrical signal for both power & data, with no measurable noise |

| » Robust industrial design provides reliable long lasting performance | » Remains unaffected by machine vibration or rotational speed |

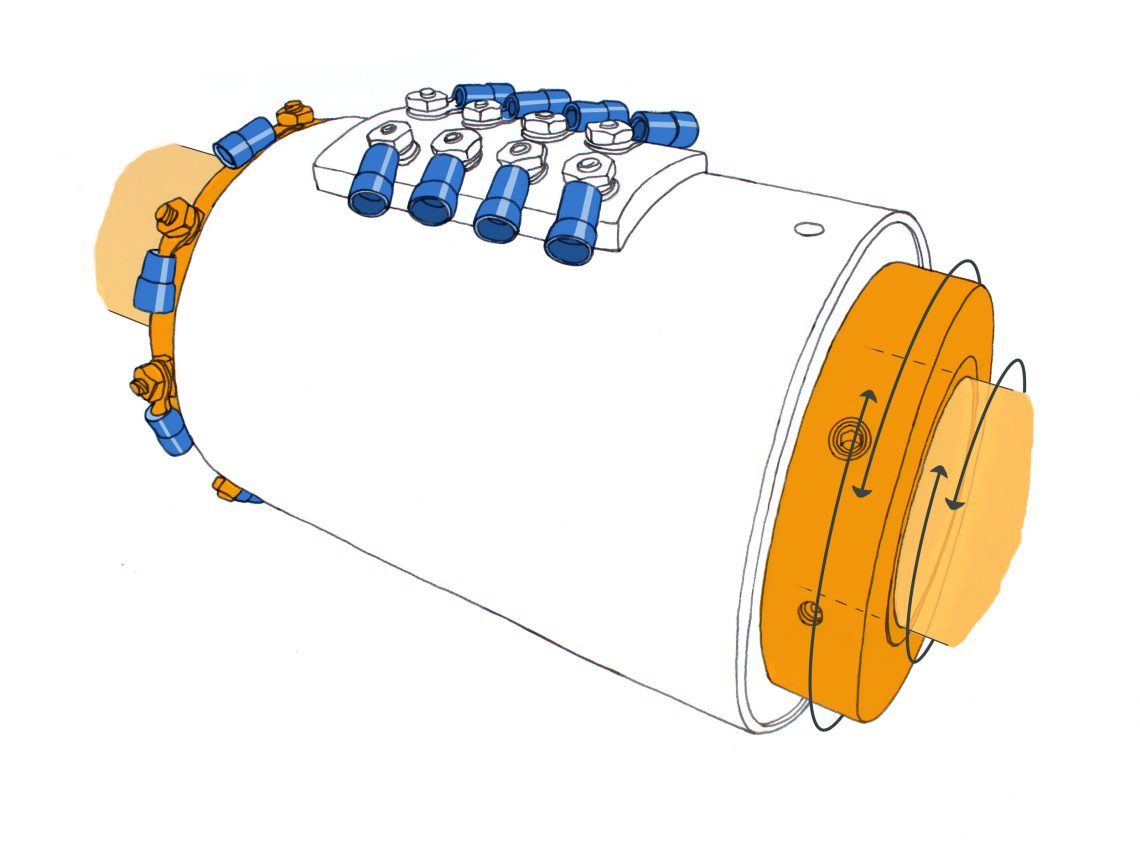

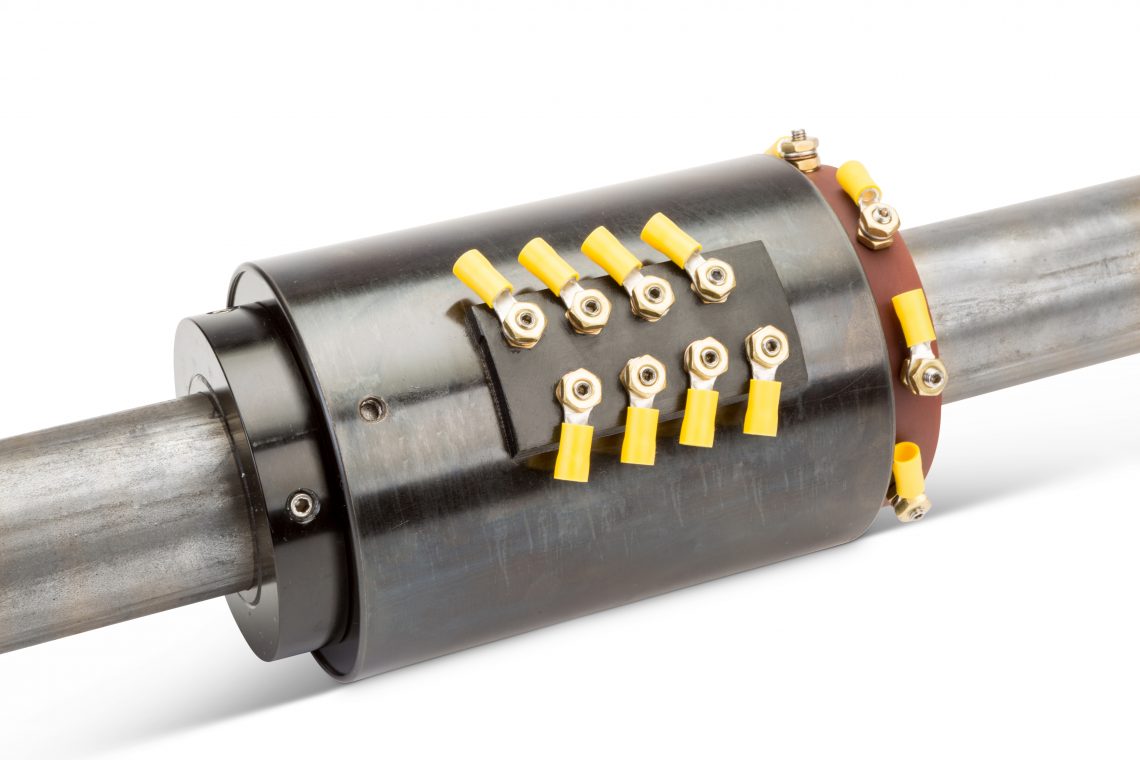

Meridian Laboratory’s MXT Through-Hole Series is designed for applications which require mounting on solid or hollow shafts. Offered in a wide variety of sizes up to 4.00” diameter, the shaft can be utilized as a drive shaft for the rotary portions of a machine, or for hydraulic or pneumatic lines through the center of the unit. Meridian Laboratory also offers fully integrated solutions with rotating unions and other add-ons.

Like all other ROTOCON rotating electrical contacts, the MXT through-hole slip ring series is designed to accommodate signal/data level transmission, (see full list below) as well as high current power transfer. Similarly, the ROTOCON MXT through-hole series remains unaffected by machine vibration or rotational speed, throughout its entire RPM range. The ROTOCON MXT through-hole series is offered in a variety of electrical termination options including ring terminals, flying leads, MIL-spec, or wet-mate connectors on both rotating and stationary ends.

Why Choose ROTOCON? Request a ROTOCON quote