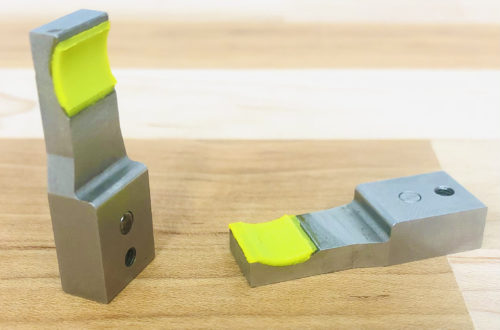

Meridian Laboratory solutions will improve friction and meet all non-marking / no rejection specifications (As demonstrated in a case where ML6 delivered perfect grip for robotic fingers).

ML6® Bonding Strength and Longevity

Material will not Separate, Chip, Break, or Crumble

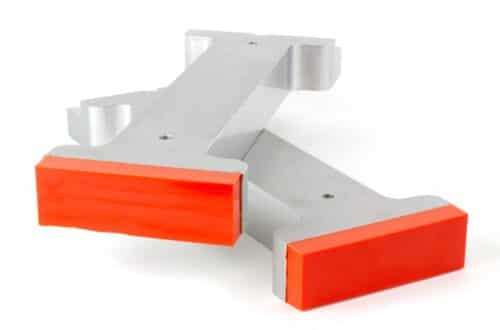

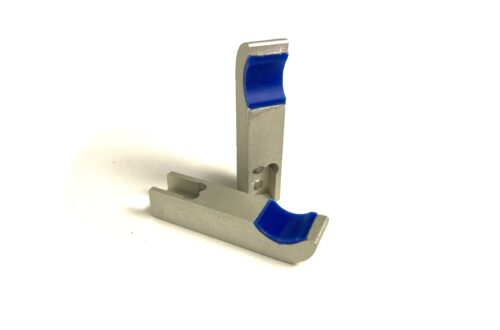

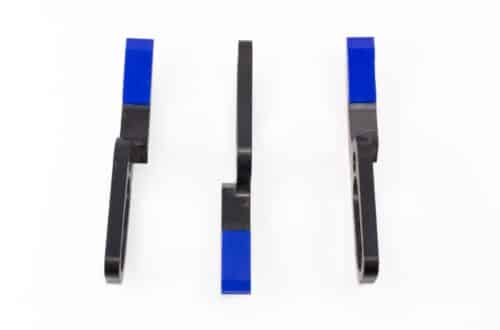

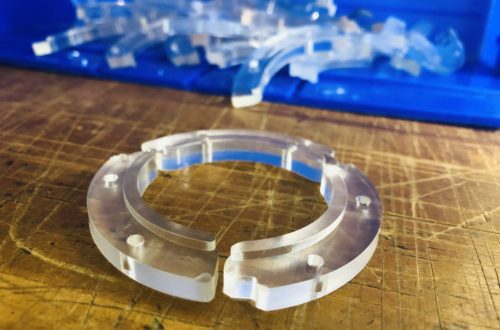

Meridian Laboratory ML6 precision polyurethane is cast/bonded right to the base material (not rubber pieces glued on, like other manufacturers). Base materials and properties range from all grades of steel, stainless steel, aluminum, brass, copper, ceramics, plastics, and a wide variety of other exotic metals and polymers.

Our process, perfected over 55 years of real world experience, guarantees an extremely strong bond between the ML6® material and any work-holding, jaw, jig, fixture, chuck, or robotic finger. In fact, the bond is so strong the polyurethane material would tear before the bond separates or breaks. This is especially important in high-friction and high-precision applications. Through Meridian Laboratory’s unique and exclusive manufacturing process, we are able to coat very select and intricate profiles / contours to match any product.

- Surface bond between polyurethane ML6 and a core is stronger than ML6 material itself

- Outlasts conventional over-molded rubbers, urethanes, nitriles, and other materials

- Ability to precisely coat very intricate portions of parts to specification

Customization Options

We specialize in both low and high volume orders

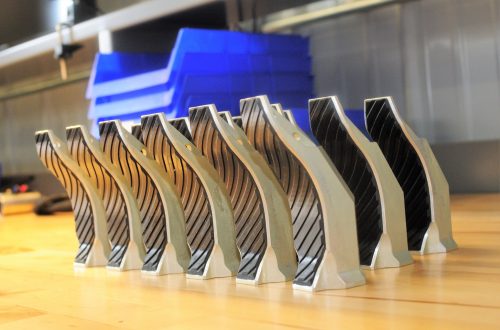

Meridian Laboratory has helped generations of engineers, designers, maintenance technicians, and innovators around the world bring their designs to life. In the past, custom precision polyurethane was an expensive and lengthy process, but that’s no longer the case. Our unique and versatile prototype and production process can deliver parts in volumes as low as one piece, in as little as 5 business days.

Typically, our customers come to us to develop a single tested and working prototype, and want to put that part into standard production once proof of concept is shown. Once we have standardized any part, it can be repeated an infinite number of times, with cost-effective and repeatable results. We manufacture and produce on a daily basis, and can deliver high-volume production runs in batch deliveries to meet your needs and usage patterns.

- Prototypes available in as little as 5 business days

- Tolerances of 0.001” or better in both diameter and runout

- Single prototypes to high-volume production, in an efficient and cost-effective way

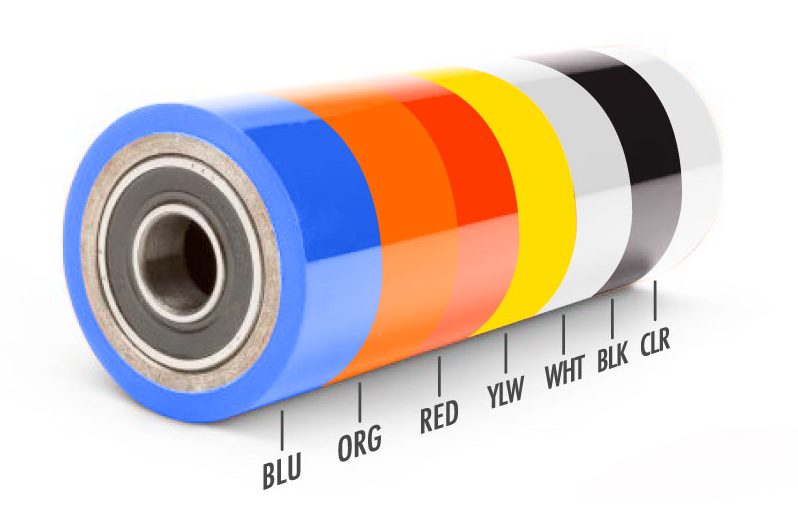

Check out our durometer options below, our engineers can help find the best option to suit your different applications (hard/durable to soft/forgiving).

Custom colors available on request

| ML6-40A | ML6-55A | ML6-70A | ML6-80A | ML6-90A | ML6-60D | |

|---|---|---|---|---|---|---|

| Hardness (+/- 5) | 40A | 55A | 70A | 80A | 90A | 60D |

| Ultimate Elongation (%) | 640 | 540 | 540 | 640 | 500 | 300 |

| Ultimate Tensile (PSI) | 3200 | 5300 | 5600 | 6900 | 6200 | 6400 |

| Tear Strength, pli Die "C" | 150 | 244 | 332 | 421 | 568 | 620 |

| Split | 19 | 51 | 92 | 175 | 134 | 125 |

| Compression Modulus (Young's Modulus) | 380 | 830 | 1660 | 1990 | 6460 | 16200 |

| Compression Set (% 22 Hrs. @ 158ºF) | 0 | 1 | 7 | 16 | 18 | 30 |

| Bashore Rebound (%) | 50 | 41 | 37 | 31 | 35 | 52 |

| Abrasion Loss, mm | 200 | 224 | 159 | 94 | 101 | 115 |

For more information, contact Meridian Laboratory