Why Precision Matters

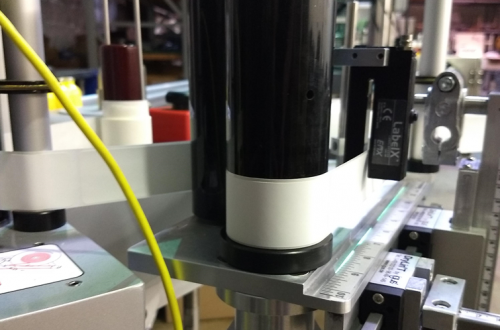

While it’s easy to think “it’s just a roller”, it’s even easier to lose sight of how much you ask of your rollers and wheels, day in and day out. Keeping your operations running with a minimum of downtime for machine repairs, feed jams, or other time wasters (and money costers) means upgrading to superior components for your application. If you expect and demand that your equipment do more, ML6 offers a proven upgrade you’ll notice immediately.

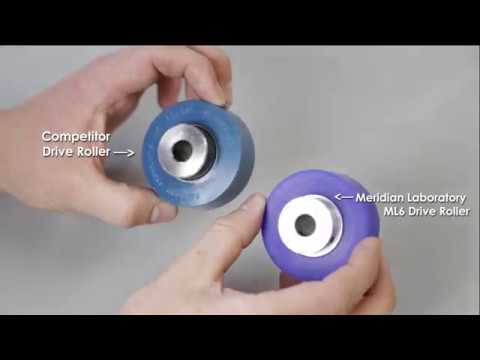

Take a look at the short video below to see one (of many) very simple reasons a more durable, precision roller can have a huge impact on your manufacturing environment.

The Importance of Total Indicated Runout When Selecting Polyurethane Rollers

Better Overall Quality

All these factors combined translate into a better polyurethane product that is consistent and accurate in manufacturing and production processes, which in turn provides:

- A more uniform and consistent end product

- Less maintenance and downtime

- More profit

Manufacturers Supported

| Pitney Bowes | Mailcrafter | Condes |

| Bell and Howell | Lasermax | Halmjet |

| Multi-Feeder | F.L. Smithe | Honsel |

| Sure-Feed | Winkler & Dunnebeir | International |

| GBR | Beasley | Kemp |

| MBO | Beck | PAHL |

| OCE | Butler | Pavema |

| Streamfeeder | Cheetah | RYOBI |

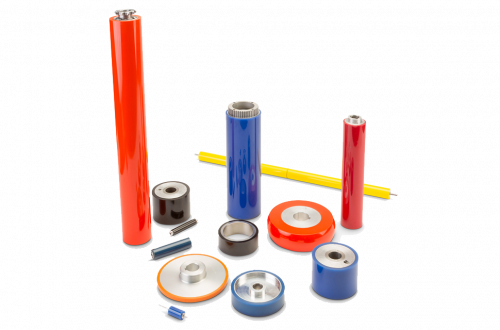

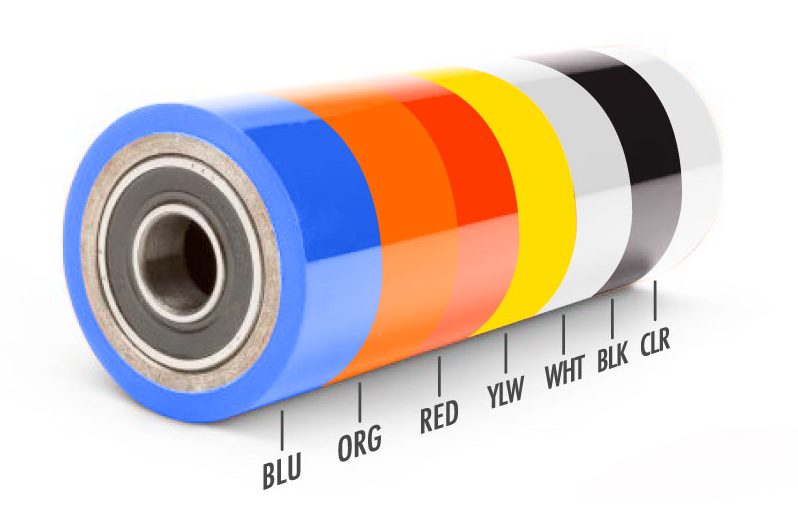

Meridian Laboratory’s ML6 product line, which includes rollers, wheels, sheets, and tubes, is the result of a long history of optimized and custom solutions for our customers. Contact us to learn more.

| ML6-40A | ML6-55A | ML6-70A | ML6-80A | ML6-90A | ML6-60D | |

|---|---|---|---|---|---|---|

| Hardness (+/- 5) | 40A | 55A | 70A | 80A | 90A | 60D |

| Ultimate Elongation (%) | 640 | 540 | 540 | 640 | 500 | 300 |

| Ultimate Tensile (PSI) | 3200 | 5300 | 5600 | 6900 | 6200 | 6400 |

| Tear Strength, pli Die "C" | 150 | 244 | 332 | 421 | 568 | 620 |

| Split | 19 | 51 | 92 | 175 | 134 | 125 |

| Compression Modulus (Young's Modulus) | 380 | 830 | 1660 | 1990 | 6460 | 16200 |

| Compression Set (% 22 Hrs. @ 158ºF) | 0 | 1 | 7 | 16 | 18 | 30 |

| Bashore Rebound (%) | 50 | 41 | 37 | 31 | 35 | 52 |

| Abrasion Loss, mm | 200 | 224 | 159 | 94 | 101 | 115 |

For more information, contact Meridian Laboratory